1.Cost-Effective Transportation:

One of the most significant advantages of delivering aluminum honeycomb cores in a compressed state is reduced transportation costs. By minimizing the volume of products during shipping, companies can save considerably on freight charges. The lightweight nature of aluminum also contributes to lower shipping costs.

2.Preservation of Product Integrity:

The compressed delivery form helps protect the aluminum honeycomb cells from physical damage during transportation. The packaging is designed to keep the cores intact, reducing the risk of deformation or other structural issues that could occur if the products were shipped in an expanded state.

Space Efficiency:

Compressed aluminum honeycomb cores take up less space, allowing for higher density in transport and storage. This is especially beneficial for businesses with limited warehouse space or those looking to optimize their logistics operations.

Versatile Applications:

These core products can be utilized in various applications across different industries. In aerospace, they are used for aircraft panels, in automotive for lightweight structural components, and in construction for wall panels and facades. The versatility of these materials contributes to their widespread appeal.

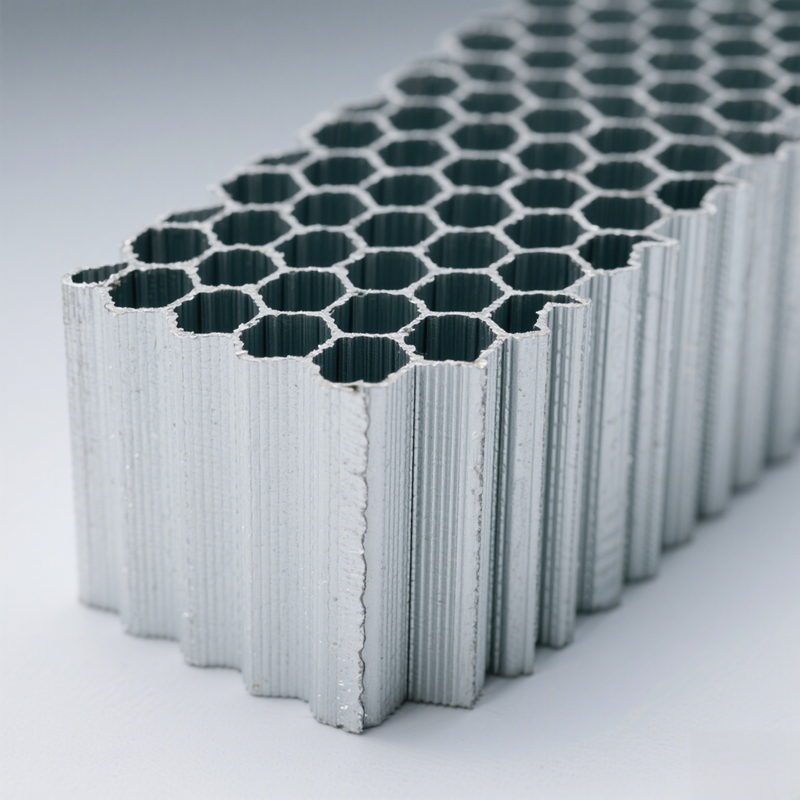

3.High Strength-to-Weight Ratio:

Aluminum honeycomb cores are renowned for their strength-to-weight ratio, making them ideal for load-bearing applications while remaining lightweight. This property ensures that structures made from these materials can bear significant loads without adding excessive weight.

4.Customizability:

The manufacturing process allows for customization in terms of cell size, thickness, and overall dimensions based on the specific needs of the application. This adaptability enables manufacturers to meet exact specifications required by their clients.

Thermal and Acoustic Insulation:

The honeycomb structure provides excellent thermal and sound insulation properties. This makes compressed aluminum honeycomb cores suitable for use in applications where noise attenuation and thermal management are crucial.

Post time: Apr-15-2025