-

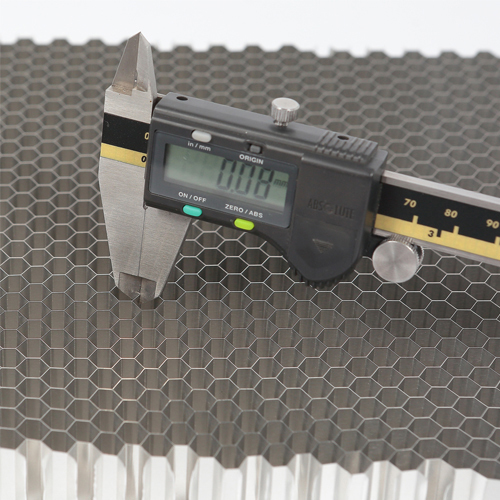

Aluminum honeycomb core expanded application to Air condition

The unique features of our aluminum honeycomb core extensions make them ideal for a variety of applications. The hexagonal cell structure provides excellent strength and rigidity, resulting in enhanced load-bearing capacity. Its lightweight nature makes it easy to handle and install, reducing labor costs and time. In addition, our core materials have excellent thermal and acoustic insulation properties, making them ideal for air conditioning system applications.

The use of our aluminum honeycomb cores in air conditioners has revolutionized the industry, taking the efficiency and performance of these systems to new heights. The honeycomb structure allows for optimal air distribution, ensuring equal cooling and ventilation in every corner of the space. Not only does this improve comfort, it also helps save energy, making it an environmentally friendly choice.

-

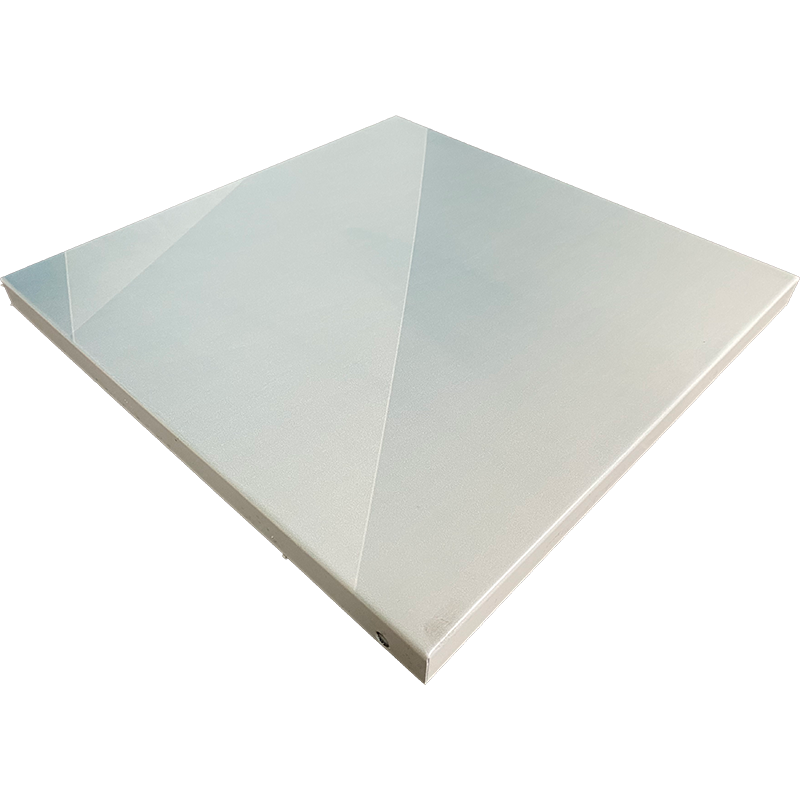

Aluminum honeycomb panel used for building decorations

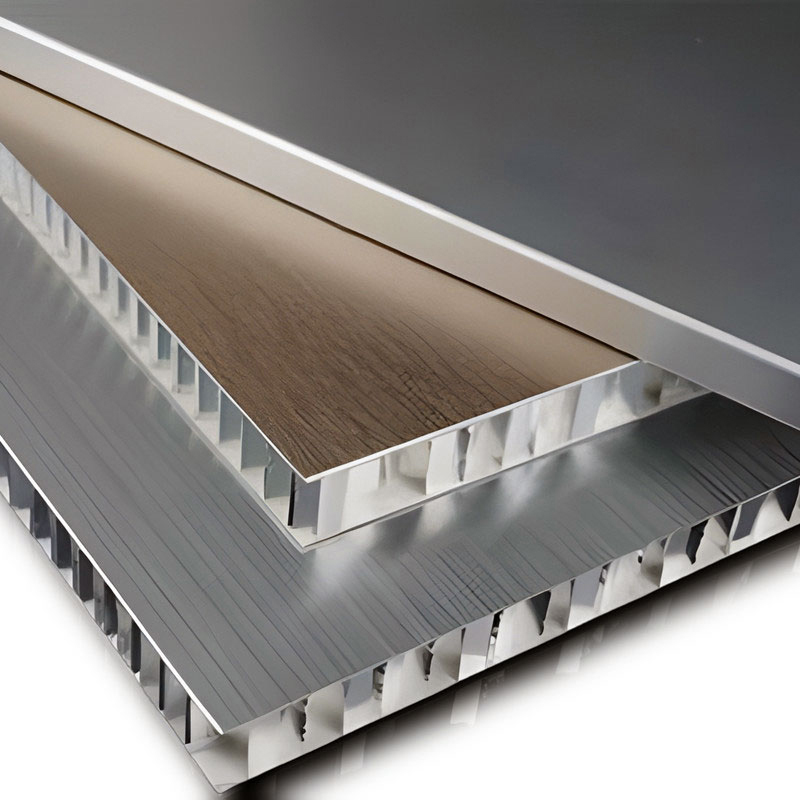

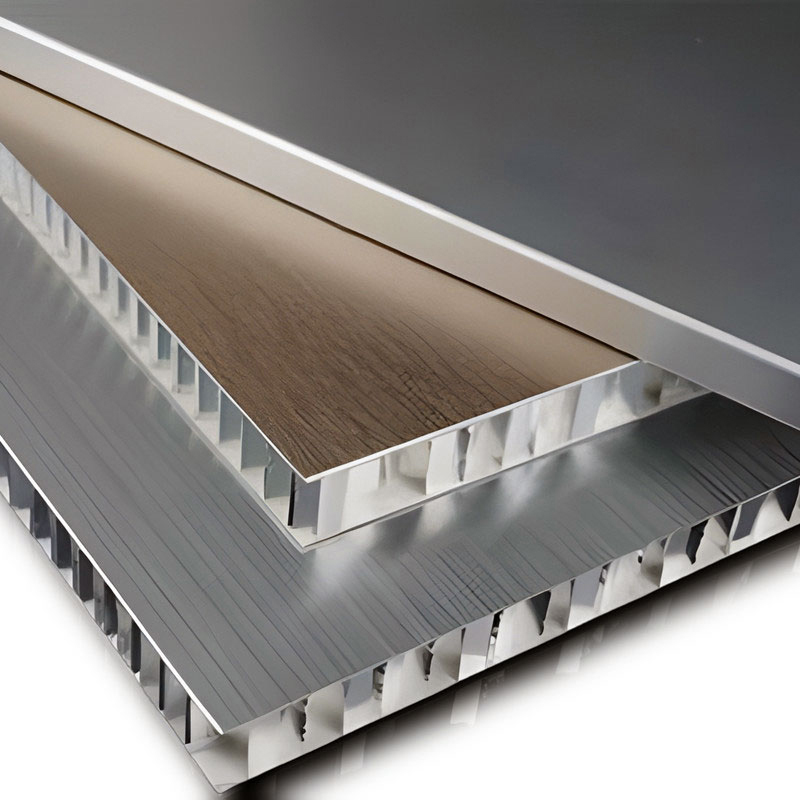

Aluminum honeycomb panel is a composite material known for its outstanding product properties. High-end construction companies in the construction field use this sheet due to its high strength; not easily bent and has a high level of flatness. It is also very easy to install. This panel has an excellent strength to weight ratio, making it the perfect solution for many projects. The field of application of this product is constantly expanding and it is well known in the construction market.

-

Wall Decoration Materials Aluminum Composite Honeycomb Panels

our honeycomb composite panels have proven to be indispensable in conventional areas as well. They have been widely used in more than 20 fields, including the construction of high-speed rail and airport ceilings and partitions. Their excellent strength-to-weight ratio makes them ideal for use as high-speed rail built-in partitions. Furthermore, our panels have been utilized in the creation of interior and exterior curtain walls for various construction projects.

-

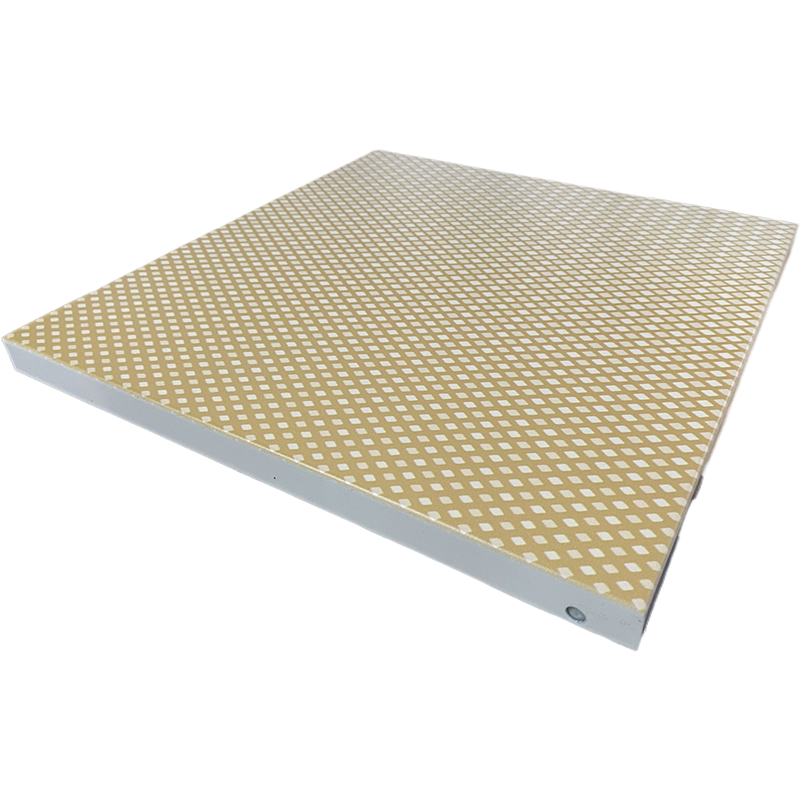

4×8 Composite honeycomb panels manufacturer VU laser printing

Composite honeycomb panel generally does not require large installation equipment, suitable for unit curtain wall installation. The material is lightweight and can be fixed with ordinary binder, thus reducing installation costs. The sound insulation and heat insulation effect of composite honeycomb board are better than that of 30mm thick natural stone board.Our products are mainly aluminum alloy sheet, other metals as a supplement, in the middle is in line with the United States aviation standards of aluminum honeycomb. Our company adopts composite process cold pressing and hot pressing technology, specializing in the production of metal honeycomb composite panel products, products are aluminum honeycomb panel, titanium zinc honeycomb panel, stainless steel honeycomb panel, stone honeycomb panel.

-

Cutting-edge Honeycomb composite panel 4×8 from China supplier

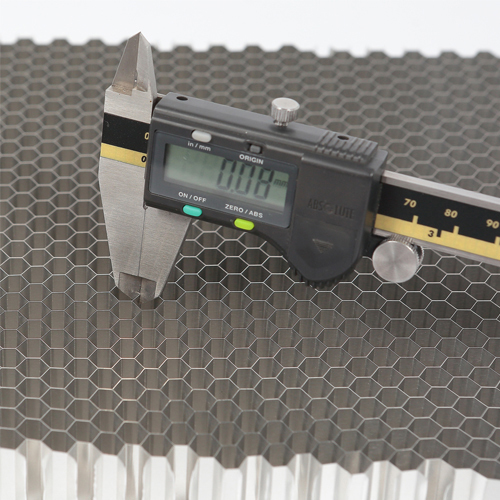

Our cutting-edge product the honeycomb composite panel supplied directly from China. Our panels are manufactured to meet the high standards required by the public, with standard sizes available, such as the popular 4X8 size. We take pride in the accuracy of our products, ensuring that they can be controlled within a tolerance range of +-0.1.

The composite materials used in our panels allow for flexible customization, catering to the specific needs and requirements of our customers. This flexibility enables us to create exquisite finished products that are tailored to meet individual specifications.

-

Honeycomb board composite marble

Aluminum honeycomb panel + composite marble panel is a combination of aluminum honeycomb panel and composite marble panel.

Aluminum honeycomb panel is a lightweight, high-strength building material with excellent heat insulation, fire prevention, and earthquake resistance. The composite marble sheet is a decorative material mixed with marble particles and synthetic resin. It not only has the natural beauty of marble, but also has the durability and easy maintenance of synthetic materials. By combining aluminum honeycomb panels with composite marble panels, the advantages of both can be brought into play.

-

Lightweight Composite Honeycomb Core Board Supplier

Honeycomb aluminum panel is a series of metal composite panel products developed by combining composite honeycomb panel technology in aviation industry. The product adopts “honeycomb sandwich” structure, that is, the high strength alloy aluminum plate coated with decorative coating with excellent weather resistance as the surface, bottom plate and aluminum honeycomb core through high temperature and high pressure composite made of composite plate. Honeycomb aluminum plate is a box structure wrapped around the edges, with good tightness, improve the safety and service life of honeycomb aluminum plate. When the base and surface layer of honeycomb aluminum plate are installed, corner codes and screws are used to connect, eliminating skeleton welding, and there is no nail on the site after the surface layer is installed, which is clean and tidy.

-

Coated Aluminum Honeycomb Panel

Forms: PVDF or PE coating can be used according to the application scene.

Color: It can be selected according to the international standard RAL color card.

Features: rich color choices, small batch customization, quality assurance.

-

Metal mirror composite honeycomb panel

Made of metal mirror aluminum, stainless steel and other high-quality materials, this panel is very suitable for interior decoration, such as shopping mall elevators, hotel design and various decorative applications.

-

Metal Honeycomb Panel for Wall Cladding

The metal honeycomb panel is made of high-quality materials including metallic mirror aluminum, stainless steel and other high-quality components. Designed specifically for interior decoration, it is ideal for enhancing the beauty of various environments, such as shopping mall elevators, hotel designs and other decorative applications. Metallic mirror aluminum not only adds luxury and modernity, but also offers excellent corrosion resistance. The combination of stainless steel and other composite materials enhances the overall durability and stability of the panels, ensuring a high-quality and long-lasting structure.

-

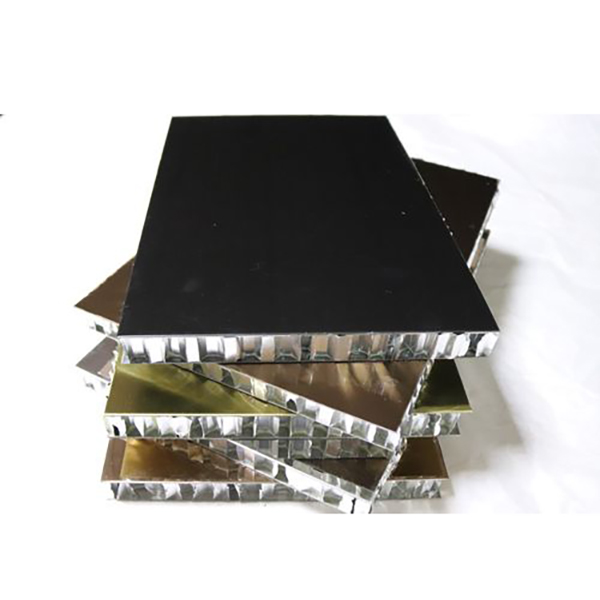

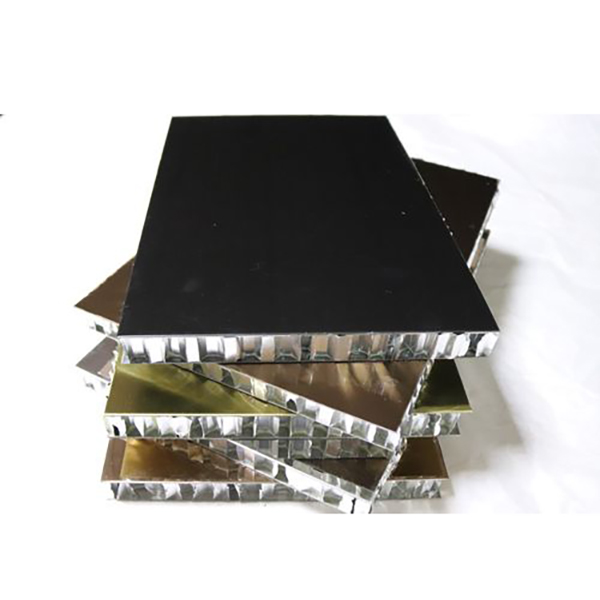

Aluminum Honeycomb Core With Composite of Variety Plates

Aluminum honeycomb core is made up of layers and aluminum foil adhesive, overlying, and then stretched into a regular hexagonal honeycomb core. Aluminum honeycomb core hole wall with sharp, clear, without burrs, suitable for high quality across the core material of adhesive and other purpose. Honeycomb board core layer is hexagonal aluminum honeycomb structure, containment of dense honeycomb like many wall beams, can bear the pressure from the other side of the panel, the plate force uniform, ensure the panel in a large area can still keep high flatness. In addition, the hollow honeycomb can also greatly abate the plate body thermal expansion. In the form of the supply full blocks of honeycomb. Cut slices of honeycomb, expanded honeycomb, perforated honeycomb, corrosion treated honeycomb.

-

Aluminum Honeycomb Perforated Acoustic Panel

A cutting-edge material designed to provide a range of exceptional features and benefits. Main features: Large Surface Area and High Flatness: The panel boasts a generous surface area and excellent flatness, ensuring a visually appealing and seamless appearance in any environment.