Exterior wall panels play a vital role in protecting buildings from harsh weather. Weather resistance ensures that structures can withstand rain, humidity, and strong sunlight without damage. Many wall panel systems, like Aluminum Honeycomb Panels, offer impressive strength and longevity. Modern designs include features such as proper flashing and sealants, which help prevent leaks and improve durability. These solutions not only extend the life of building exteriors but also reduce long-term maintenance for both homeowners and professionals.

Weather Resistance in Exterior Wall Panels

Moisture Protection

Moisture is one of the biggest threats to building exteriors. Exterior wall panels use several mechanisms to keep water out and protect the structure. Many panels feature layers that block rain and humidity. Some systems use drainage channels to guide water away from the wall. Others rely on drying methods that allow trapped moisture to escape.

Note: The “belt and suspenders” approach means designers use multiple layers of defense against condensation. This helps prevent water damage and mold growth.

Here is a table showing common moisture control mechanisms in wall systems:

| Wall System Type | Moisture Control Mechanism |

| Face-Sealed Wall Systems | Deflection |

| Drained/Screened Systems | Drainage |

| Mass Wall Systems | Drying |

Many panels also include features like vapor retarders, air barriers, insulation, and special finishes. These layers work together to improve Weather Resistance and keep interiors dry. Modern panels, such as Aluminum Honeycomb Panels, offer advanced protection compared to traditional siding. For example, traditional stucco allows water vapor to pass through, which helps prevent moisture damage. However, stucco can crack under stress, leading to water infiltration. Newer panels often have non-porous surfaces and drainage systems that reduce the risk of trapped moisture.

UV and Sun Defense

Sunlight can cause fading and weaken materials over time. Exterior wall panels are designed to resist UV rays and maintain their appearance. High-pressure laminate (HPL) panels are treated to block harmful UV rays. This treatment helps keep colors vibrant and reduces the need for repainting. PVC panels use advanced UV-resistant compounds that prevent color fading and material degradation. These panels stay bright and strong even after years of sun exposure.

- HPL panels maintain color stability and resist degradation.

- PVC panels create an impermeable barrier against moisture and UV rays.

- Many panels combine moisture protection with UV defense for better Weather Resistance.

Aluminum Honeycomb Panels also offer excellent sun defense. Their surface resists scratches and fading, making them a reliable choice for building exteriors. These panels help preserve the structural integrity and appearance of the building.

Temperature and Climate Performance

Exterior wall panels must withstand temperature swings and extreme weather. Materials like wood plastic composite (WPC) can endure temperatures from -30°C to 70°C without cracking or warping. Composite panels handle variations from -40°F to 160°F and remain stable. Insulated metal panels provide strong protection against severe weather conditions. They enhance air, thermal, and moisture protection, which improves energy efficiency and reduces installation costs.

Tip: In regions with extreme climate variations, insulated metal panels offer cost savings and long-lasting performance.

Metal wall panels are tested to withstand harsh weather events. They ensure durability and functionality for homeowners in challenging climates. Aluminum Honeycomb Panels deliver high flatness and strength, making them suitable for areas with frequent temperature changes. These panels contribute to the overall Weather Resistance of the building envelope.

Durable Materials and Technologies

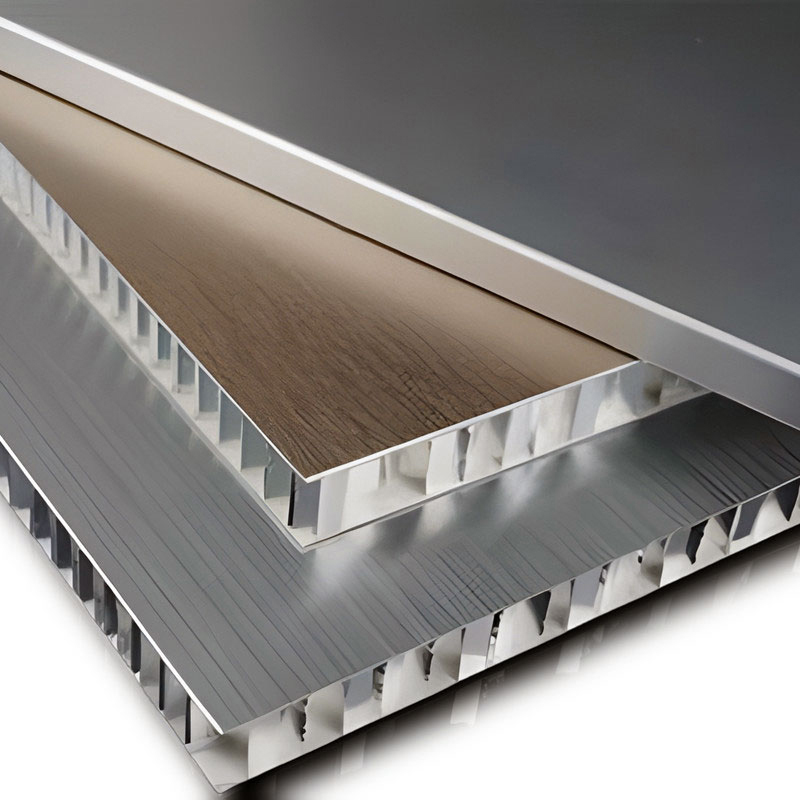

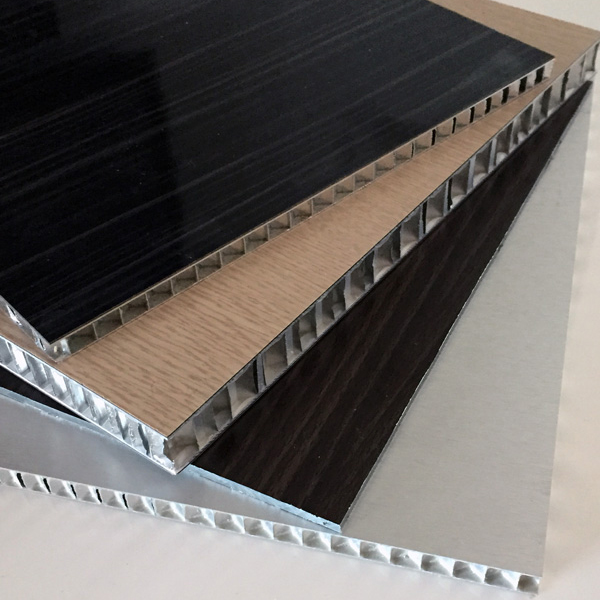

Aluminum Honeycomb Panel Features

Chenshou Tech’s Aluminum Honeycomb Panel stands out as a top choice for exterior wall applications. This panel combines advanced engineering with practical benefits. The honeycomb structure uses two thin aluminum sheets bonded to a lightweight core. This design creates a panel that is both strong and light.

Here is a table showing the key features that enhance the durability of Aluminum Honeycomb Panels:

| Feature | Description |

| Light weight and high strength | Aluminum honeycomb panels are significantly lighter than solid panels while maintaining high strength. |

| Excellent compression and bending resistance | The honeycomb structure disperses pressure and bending forces effectively. |

| Good thermal and sound insulation properties | The air-filled honeycomb core provides excellent insulation against heat and sound. |

| Fire retardant performance | Made from fire-resistant materials, these panels help prevent fire spread and reduce damage. |

- The I-beam effect in the honeycomb core gives the panel stiffness and resistance to bending without adding extra weight.

- Reliable flatness prevents warping and buckling, which ensures clean lines on building exteriors.

- PVDF coatings on the surface provide weather and corrosion resistance, making the panels durable in harsh environments.

Aluminum honeycomb panels also have a high strength-to-weight ratio. This makes them superior to many other materials, such as marine plywood, when stiffness and low weight are important. These panels are easy to install and help reduce the overall weight of the building structure.

Other High-Performance Materials

Many other materials are used for exterior wall panels. Each material offers unique benefits and challenges. The table below compares some of the most durable options:

| Material Type | Durability & Resistance | Maintenance Requirements | Aesthetics & Style | Insulation & Energy Efficiency | Installation & Cost Considerations |

| Fiber Cement Panels | Highly durable; fire-resistant; resists termites & mold | Minimal upkeep; difficult to cut; heavy | Mimics wood, stone, brick; suited for modern/industrial | Requires additional insulation; long lifespan (30-50 yrs) | Professional installation often needed; mid-range cost |

| Metal Siding (Aluminum/Steel) | Durable; resistant to rot, pests, weather; prone to dents | Low maintenance; may need dent repairs | Modern, sleek, industrial aesthetic | Poor insulator; needs extra insulation layers | Requires corrosion-resistant fasteners; higher cost |

| Vinyl Panels | Moisture resistant; prone to warping, cracking, fading | Easy to clean; DIY-friendly | Variety of colors and wood-look finishes | Needs additional insulation for energy efficiency | Budget-friendly; easy installation; lower durability |

| Composite Wood Slat Panels | Weather-resistant; fire-resistant; pest-resistant | Minimal maintenance; no regular treatments | Realistic wood look; suits modern and rustic styles | Natural thermal regulation; improves indoor comfort | Slightly higher cost; straightforward installation |

| Natural Wood Panels | Classic appeal; moisture and pest susceptible | Requires regular sealing/staining | Timeless, warm aesthetic | Provides insulation but less energy efficient | Installation varies; ongoing maintenance increases cost |

Fiber cement and wood plastic composite (WPC) panels are also popular for their durability and long service life. The table below highlights their performance:

| Feature | WPC Panels | Fiber-Cement Panels |

| Weather Resistance | Excellent moisture resistance; repels water, preventing rot and mold growth. | Robust against extreme weather; withstands high winds, hail, and freeze-thaw cycles. |

| Longevity | Long lifespan with warranties of 25 years or more; resistant to scratches and dents. | Can last for decades with proper installation and maintenance; excellent color retention. |

| Fire Resistance | Moderate; potential fading from sunlight exposure. | High fire ratings (Class A); suitable for fire-prone areas. |

| Maintenance | Requires less frequent repairs due to dimensional stability. | Needs proper installation and maintenance to avoid moisture-related issues. |

These materials offer strong protection and can meet the needs of different building projects. Fiber cement panels resist fire and pests, while WPC panels excel at repelling moisture and preventing rot.

Advanced Coatings and Treatments

Modern wall panels often use advanced coatings and treatments to improve their durability. These coatings protect panels from UV radiation, moisture, and pollutants. They also help maintain the panel’s appearance and extend its service life.

- Wall cladding coatings provide moisture resistance and UV protection, which are essential for durability in harsh climates.

- These coatings enhance protection against environmental elements like salt corrosion and humidity, especially in coastal areas.

- High-quality coatings can reduce long-term maintenance needs, making them a cost-effective choice for building owners.

Some coatings, such as polyurethane, flex with temperature changes. This flexibility prevents cracks and can extend the panel’s service life by up to 20 years. Polyurea coatings cure quickly and form a tough, waterproof barrier. This barrier protects panels from extreme weather and can extend longevity by up to 25 years.

Tip: Advanced coatings not only improve durability but also boost energy efficiency by reflecting sunlight and reducing heat absorption.

These technologies, combined with strong core materials, help exterior wall panels achieve high levels of Weather Resistance and long-term performance.

Maintenance and Longevity

Routine Care Needs

Regular maintenance helps exterior wall panels last longer and look their best. Most panels need only basic care throughout the year.

- In spring, clean panels and check for any damage from freezing and thawing.

- During summer, inspect for fading caused by sunlight and apply protective coatings if needed.

- In fall, examine fasteners and seals before winter storms arrive.

- In winter, watch for ice buildup but avoid heavy cleaning that could damage the surface.

General care tips include:

- Clean panels every 3–6 months using a soft cloth and mild detergent to remove dust and stains.

- Inspect joints and seals for gaps or wear to prevent water from seeping in.

- Check for surface scratches and make sure all fasteners are tight, especially after storms.

- Use pads on nearby furniture to prevent scratches, and avoid sharp tools near the panels.

- In sunny areas, use curtains or UV-blocking films indoors to reduce UV damage.

- In damp spaces, use a dehumidifier to prevent mold growth.

Tip: Routine inspections and gentle cleaning can prevent costly repairs and extend the life of your panels.

Panel Lifespan Comparison

Different materials offer different lifespans and maintenance needs.

- Wood plastic composite (WPC) panels require little upkeep—just regular cleaning with soap and water. They can last 20–30 years with minimal care.

- Traditional wood siding needs more attention, such as sanding, painting, and anti-termite treatments. Wood usually needs replacement every 10–15 years.

The table below shows key factors that affect how long panels last:

| Factor | Description |

| Quality of Materials | High-quality materials resist wear and last longer. |

| Environmental Conditions | Extreme temperatures, moisture, and UV rays can shorten panel lifespan. |

| Installation Practices | Proper installation prevents warping, moisture problems, and loss of strength. |

Signs of Wear and Replacement Timing

Knowing when to replace exterior wall panels helps protect your building. Common signs include:

- Bubbling or blistering, which shows moisture is trapped under the surface.

- Cracks, chips, or rotting, which weaken the panel and allow water in.

- Warped or gapping panels, which reduce weather protection.

- Fading or discoloration, which means the panel’s protective layer is wearing out.

- Mold, mildew, or dark spots, which signal moisture problems and possible health risks.

- Needing frequent repairs, which suggests the panels are reaching the end of their lifespan.

Note: If your panels show several of these signs or are nearing their expected lifespan, consider planning for replacement to maintain your building’s safety and appearance.

Choosing Panels for Different Climates

Humid and Rainy Areas

Selecting the right exterior wall panels for humid and rainy climates is important for building protection. Materials that resist moisture and prevent mold growth work best in these environments. The table below shows how common panel materials perform in wet conditions:

| Material Type | Maximum Moisture Content | Mold Growth Threshold |

| Solid Wood | 19% | 16% |

| Plywood | 16% | 14% |

| OSB | 16% | 13% |

Panels made from solid wood, plywood, and OSB can absorb moisture, but each has a different threshold before mold starts to grow. For better performance, many builders choose metal panels with corrosion-resistant finishes or panels with advanced coatings. These options help prevent water damage and extend the life of the building. Other good choices include clay or concrete tiles with proper underlayment and asphalt shingles with algae-resistant coatings.

Tip: In areas with heavy rainfall, always check that wall panels have proper drainage systems and sealed joints to keep interiors dry.

Hot and Sunny Regions

In hot and sunny climates, panels must resist UV rays and high temperatures. Hardie fiber cement siding is engineered for these conditions. It resists blistering heat, humidity, and strong sunlight. This material is non-combustible and maintains its color over time. WoodyWalls WPC panels also perform well. They are fully waterproof and UV-resistant, offering a wood-like look with less maintenance.

Panels with cool wall technology reflect sunlight and release heat quickly. This helps lower indoor temperatures and reduces energy costs. For example:

- Cool walls reflect more sunlight than standard panels.

- High thermal emittance allows panels to release absorbed heat.

- In warm climates, cool walls can save up to 11% on HVAC energy for retail stores and up to 27% for homes.

Cold and Windy Zones

Cold and windy regions require panels that block drafts and retain heat. Materials like brick, fiber cement, and WPC offer strong weather resistance and durability:

| Material | Durability and Weather Resistance |

| Brick | Withstands fire, pests, and harsh weather; lasts over 100 years. |

| Fiber Cement | Resists fire, insects, and rot; low-maintenance, enduring 100+ years. |

| WPC (Wood-Plastic Composite) | Waterproof, UV and weather resistant; requires very low maintenance. |

Insulating exterior walls is essential in cold climates. Proper insulation traps heat during winter and keeps interiors comfortable. Continuous insulation systems create a thermal break, reducing heat loss and lowering energy bills. Materials like mineral wool or rigid foam board work well for this purpose.

Note: Always choose panels with strong insulation and wind resistance for buildings in cold or exposed locations.

Benefits of Weather-Resistant Panels

Cost Savings and Value

Weather-resistant exterior wall panels help save money over time. These panels need less maintenance, which means fewer repairs and replacements. Insulated panels also help keep indoor temperatures steady, so energy bills go down. Durable materials last longer, so homeowners and building owners spend less on upkeep.

| Benefit | Description |

| Reduced Maintenance Costs | High-quality panels need little upkeep, so repairs and replacements are rare. |

| Lower Energy Bills | Insulated panels keep heat in or out, which lowers energy use and costs. |

| Increased Durability | Strong materials resist damage, so panels last longer and save money. |

Many property owners also see higher resale values when they use weather-resistant panels. Insurance companies may offer lower premiums for buildings with wind-resistant features. Wind mitigation inspections can lead to discounts on hurricane and windstorm insurance. These savings add up over the life of the building.

- Homes with wind-resistant panels often qualify for lower insurance premiums.

- Wind mitigation inspections can help owners get better insurance coverage.

- Buildings with strong panels may have higher property values.

Building Protection and Safety

Weather-resistant panels protect buildings from harsh weather. They use strong materials and layered construction to stand up to storms, wind, and flying debris. Some panels are tested for hurricane impact and approved for use in high-risk areas. This protection keeps people and property safe during extreme events.

| Feature | Description |

| Robust Materials | Panels use strong materials that last through tough weather. |

| Layered Construction | Multiple layers give panels extra strength and stability. |

| Hurricane Impact Resistance | Some panels pass strict tests for hurricane zones. |

| Protection Against Projectiles | Designed to resist impacts from debris during storms. |

| Energy Efficiency | Panels help keep buildings comfortable and safe by saving energy. |

Sustainability and Environmental Impact

Many weather-resistant panels support green building goals. Manufacturers use recycled materials and eco-friendly processes. Some panels meet strict environmental standards and carry certifications that show their low impact on the planet.

- FSC Certification: Wood comes from forests managed for sustainability.

- PEFC Certification: Ensures responsible forest management and product traceability.

- Environmental Product Declarations (EPD): Shares clear details about a product’s environmental effects.

- VOC Emissions Certifications: Confirms low or zero harmful emissions.

- EU Ecolabel: Marks products with reduced environmental impact.

- Cradle to Cradle: Reviews how products are made and their effect on the environment.

Tip: Choosing panels with these certifications helps protect the environment and supports healthier buildings.

Weather-resistant and durable exterior wall panels protect buildings and lower maintenance costs. Products like the Aluminum Honeycomb Panel from Chenshou Tech offer strength, flatness, and long-lasting performance.

- Choose panels that match your climate and building needs for the best results.

- Look for advanced materials and coatings to maximize value.

For more information, consult local building experts or visit manufacturer websites to explore panel options and installation guides.

FAQ

What makes exterior wall panels weather-resistant?

Weather-resistant panels use strong materials and protective coatings. These features block moisture, UV rays, and temperature changes. Good design helps prevent leaks and damage. Panels like the Aluminum Honeycomb Panel offer extra protection with their advanced structure.

How long do Aluminum Honeycomb Panels last?

Aluminum Honeycomb Panels can last for decades. Their durable core and surface coatings resist corrosion, fading, and impact. Regular cleaning and inspections help maintain their performance and appearance.

Are weather-resistant panels easy to maintain?

Most weather-resistant panels need only basic care. Cleaning with mild soap and water removes dirt. Checking seals and fasteners keeps panels secure. Advanced coatings reduce the need for frequent repairs.

Can I use these panels in any climate?

Yes. Many exterior wall panels, including Aluminum Honeycomb Panels, work well in hot, cold, wet, or windy climates. Their design and materials help protect buildings in many environments.

Post time: Feb-10-2026