Honeycomb Core technology transforms sandwich panels by increasing strength, rigidity, and insulation. Its hexagonal cell structure helps panels resist impact and absorb energy more efficiently than traditional cores. The table below shows how recent studies highlight these improvements:

| Study | Findings | Impact on Performance |

|---|---|---|

| Crupi et al. | Cell size strongly influenced energy absorption and buckling | Improved energy absorption |

| Yahaya et al. | 55% reduction in back-face deflection with increased foil thickness | Enhanced impact resistance |

| Foo et al. | Denser core led to higher peak load and smaller damage profile | Better structural integrity |

| Shitta-Bey et al. | Cell size critical for crushing forces under low-velocity impact | Increased energy absorption |

These panels also offer practical benefits for construction and air conditioning systems, including:

- Dissipation of heat, which prevents heat buildup.

- Insulation from polypropylene cell walls and dead air space.

- Strong bonds and high peel strength.

- Superior sound absorption due to vibration damping.

Builders and engineers who buy honeycomb core products, such as the 150mm honeycomb core, support efficient, lightweight, and eco-friendly projects.

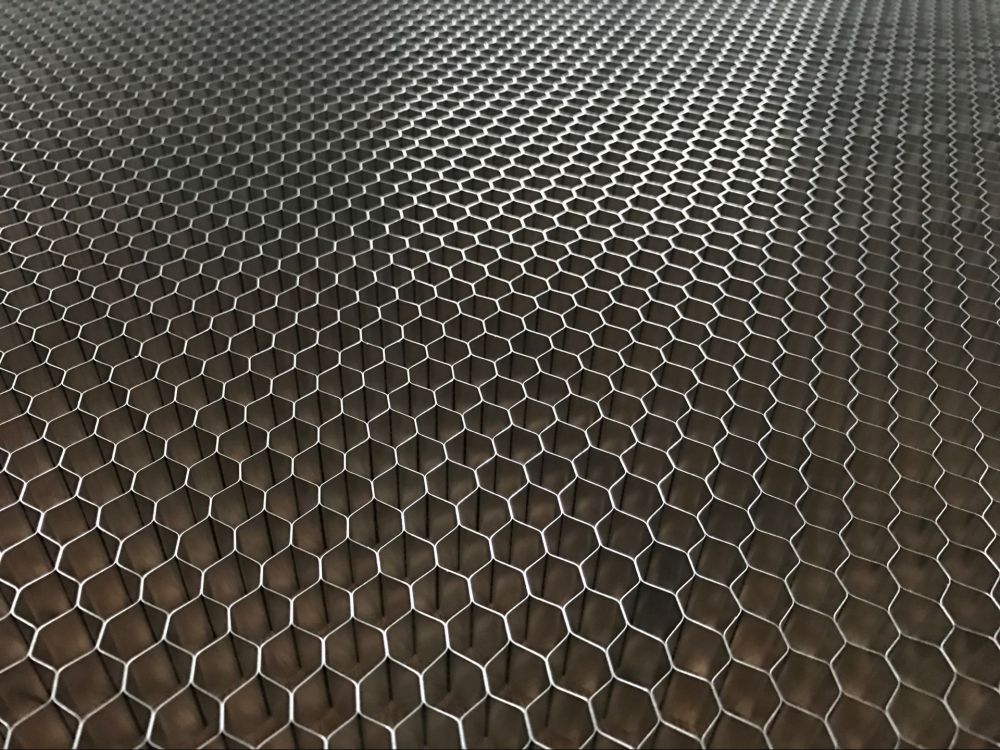

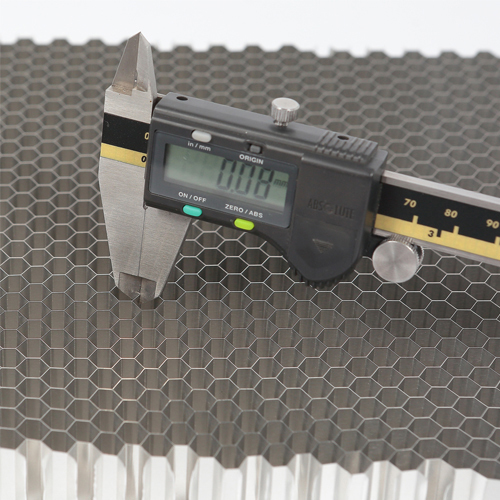

Honeycomb Core Structure

Hexagonal Cell Design

The hexagonal cell design forms the foundation of the honeycomb core. Each cell acts like a tiny pillar, distributing loads evenly across the panel. This structure increases both torsional and flexural stiffness, making sandwich panels much stronger than traditional cores. The table below shows how the hexagonal cell design boosts stiffness:

| Comparison Type | Stiffness Increase |

|---|---|

| Torsional Stiffness | 3 times higher |

| Flexural Stiffness | 8 times higher |

| Compared to Aluminum Core | 25% to 60% increase |

The geometry of the honeycomb core also affects performance. Octagonal and square cell designs help panels withstand explosive forces by improving deformation and energy dissipation. These features make honeycomb core panels ideal for demanding environments.

Chenshou Tech’s Aluminum Honeycomb Core uses this hexagonal structure to deliver exceptional flatness and rigidity. The lightweight nature of aluminum simplifies installation and reduces labor costs. Contractors can easily handle and fit panels, saving time and effort.

I-Beam Effect

The I-beam effect explains why honeycomb core panels are so rigid. In this design, the outer facesheets act as flanges, carrying most of the load. The honeycomb core serves as the web, distributing forces and increasing stiffness. This arrangement allows panels to support heavy loads without bending or breaking.

Material selection plays a key role in honeycomb core performance. Common materials include aluminum, aramid paper, fiberglass, thermoplastics, and specialty metals. Each material offers unique benefits, such as fire resistance, moisture protection, and strength-to-weight ratio.

Manufacturing processes also impact quality. Steps include extrusion of the core, thermal bonding, layering, precision cutting, and strict quality control. These processes ensure that panels meet high standards for durability and performance.

Tip: Chenshou Tech’s Aluminum Honeycomb Core is customizable, making it suitable for air conditioning systems and other applications where efficiency and easy installation matter.

Structural Benefits

Rigidity and Strength

Honeycomb Core technology increases the rigidity and strength of sandwich panels. The network of small, evenly spaced cells distributes mechanical stresses across the panel. This design helps panels resist bending and twisting. Honeycomb panels absorb impacts better than foam panels and provide greater protection and durability. Laboratory tests show that honeycomb panels have a ballistic limit of 340 m/s, which is 86% higher than aluminum foam panels. This means they can withstand stronger forces without breaking.

Manufacturing techniques also improve performance. Studies show that advanced core designs and bio-inspired reinforcements boost bending strength and stiffness. For example, triple-core topologies achieve higher bending strength than single-core designs. Assembly honeycomb structures increase peak load by 10.84% and flexural rigidity by up to 25.16%. These improvements make honeycomb panels reliable for demanding applications.

Impact Resistance

Honeycomb Core panels excel in impact resistance. The hexagonal cells absorb and spread energy from impacts, reducing damage. Researchers have tested these panels under different loading conditions. The table below summarizes key findings:

| Study | Focus | Findings |

|---|---|---|

| Goldsmith et al. | Perforation characteristics | Striker velocity, size, and shape affect ballistic limits and energy dissipation |

| Mines et al. | Low-velocity impact | Higher impact velocities increase energy absorption due to core crush stress |

| Nia et al. | Ballistic limit velocity | Cell wall folding improves energy dissipation and reduces damage zone |

| Hoo Fatt and Park | Analytical solution | Model for ballistic limits under projectile impact |

| Lin and Hoo Fatt | Refined models | Perforation of honeycomb plates with composite face-sheets |

| Liaghat et al. | Ballistic limit prediction | Model for metallic honeycombs impacted by cylindrical projectiles |

| Feli and Pour | Simulation of perforation | Consistency with experimental results for composite sandwich panels |

| Various researchers | Finite element analysis | Studied perforation under low and high-velocity impacts |

These results show that honeycomb panels can handle both low and high-velocity impacts. The panels protect structures from damage and maintain their shape under stress.

Lightweight Efficiency

Honeycomb Core panels are lightweight and strong. This combination makes them easy to transport and install. The table below compares different core materials:

| Core Material | Weight Characteristics | Implications for Installation and Transport |

|---|---|---|

| Honeycomb | Lightweight, high strength-to-weight ratio | Easier transport, reduced installation costs due to lighter panels |

| Aluminum | Moderate weight, good strength | Heavier, may increase transport costs |

| Aramid Paper (Nomex) | Very lightweight, good insulation | Beneficial for thermal applications, easier handling |

| Thermoplastics | Lightweight, variable strength | Flexible applications, can reduce transport weight |

| Carbon Fiber | Extremely lightweight, high strength | High transport efficiency, reduced fuel costs |

| Fiberglass | Moderate weight, good durability | May require more robust transport solutions |

Lighter panels mean lower labor costs and faster installation. In transportation, reduced weight improves range and efficiency. For larger vehicles, honeycomb panels allow more cargo or passengers, increasing utility.

Additional Features

Honeycomb Core panels offer more than strength and lightness. They resist fire, moisture, and corrosion. Standard tests rate these panels as A+ for fire resistance using ASTM E84 – 10a. The panels do not absorb water, so they prevent mildew and deformation. They are environmentally friendly because they do not emit harmful substances and are fully recyclable.

Note: Chenshou Tech’s Aluminum Honeycomb Core combines these benefits with easy installation and customization. Contractors and builders can rely on its performance and durability for modern projects.

Insulation and Protection

Thermal Insulation

Honeycomb Core panels provide excellent thermal insulation. The hexagonal cell structure traps air inside each cell. Air acts as a natural barrier to heat flow. This design helps keep indoor spaces cool in summer and warm in winter. Many air conditioning systems use honeycomb panels to improve energy efficiency. The panels limit heat transfer between rooms and outside environments. Builders choose these panels for walls and ceilings in modern buildings. The result is lower energy bills and more comfortable living spaces.

Acoustic Performance

Noise reduction is another important feature of honeycomb panels. The cells absorb sound waves and reduce vibrations. This makes rooms quieter and more peaceful. Schools, hospitals, and offices often use honeycomb panels to block unwanted noise. The panels work well in air conditioning ducts, where they prevent the spread of sound through ventilation systems. People notice less echo and fewer disturbances in spaces with honeycomb panels. The unique structure helps create a calm environment.

Environmental Durability

Honeycomb panels resist moisture, mildew, and corrosion. The aluminum material does not absorb water, so panels stay dry even in humid conditions. This prevents mold growth and keeps panels strong over time. The panels also withstand temperature changes and UV radiation. The table below shows how honeycomb panels handle environmental stressors:

| Factor | Description |

|---|---|

| Moisture Ingress | Panels stay dry and maintain integrity. |

| Thermal Cycling | Panels resist internal stress from temperature changes. |

| Material Aging | Panels keep their properties after long exposure to harsh environments. |

| Design Considerations | Strong joints and load paths ensure lasting performance. |

Honeycomb panels meet strict environmental standards. Many products carry certifications such as:

- ISO 14001 for environmental management.

- GreenGuard for indoor air quality.

These features make honeycomb panels a smart choice for sustainable building projects. Contractors and engineers trust them for long-term durability and protection.

Applications

Construction and Architecture

Honeycomb core panels play a vital role in modern construction. Builders use them for floors, walls, and ceilings because they offer strength and insulation. These panels help create lightweight structures that resist moisture and corrosion. Architects choose honeycomb panels for exterior cladding, which improves thermal insulation and gives buildings a sleek look.

- In a high-rise office building renovation, aluminum honeycomb panels provided a modern facade and protected against weather.

- A contemporary art museum used honeycomb panels in its walls to enhance acoustics and support large open spaces.

- The Beijing National Stadium, known as the Bird’s Nest, featured aluminum honeycomb panels for its unique exterior.

- London City Airport installed these panels to achieve energy efficiency and a modern appearance.

Chenshou Tech’s Aluminum Honeycomb Core offers customization for contractors and builders. The product comes in standard sizes or custom dimensions. Clients can select PVDF or PE coatings and choose from a wide range of colors. Small batch customization and quality assurance ensure the panels fit specific project needs.

Air Conditioning Systems

Honeycomb core panels improve air conditioning system performance. The hexagonal cell structure enhances thermal conductivity and strength. This design allows for optimal air distribution, which ensures effective cooling and ventilation. The panels help maintain comfortable temperatures and reduce energy use. Builders install honeycomb panels in air conditioning ducts and units to boost efficiency and save costs. Chenshou Tech’s Aluminum Honeycomb Core is a practical choice for these systems because it is lightweight and easy to install.

Transportation Uses

Honeycomb core panels are common in transportation. Aircraft, trains, and ships use these panels for interiors, floors, and bulkheads. The panels reduce weight, which improves fuel efficiency and increases payload capacity. They also dampen sound and resist corrosion.

| Benefit | Application Area |

|---|---|

| Weight savings | Aircraft, trains, ships |

| Acoustic damping | Aircraft cabins, train cars |

| Mechanical properties | Aircraft interiors |

| Corrosion resistance | Ship interiors, bulkheads |

| Flame resistance | Aircraft, rail cars |

| Reduced smoke emission | Aircraft interiors |

Polyaramid honeycombs are used in aircraft interiors, marine decks, and rail cars. Chenshou Tech’s Aluminum Honeycomb Core can be tailored for transportation needs, offering flexibility and durability.

Honeycomb core in sandwich panels offers many advantages:

- Superior mechanical performance and high stiffness-to-weight ratio.

- Excellent impact absorption and structural efficiency.

- Versatility in construction, air conditioning, and transportation.

Honeycomb panels are lightweight and recyclable. Their design reduces material use and lowers emissions. Aluminum honeycomb panels support sustainable building practices. Future innovations will focus on advanced materials and eco-friendly production. Chenshou Tech’s Aluminum Honeycomb Core is a smart choice for modern, efficient projects.

FAQ

What makes honeycomb core panels stronger than traditional panels?

Honeycomb core panels use a hexagonal cell structure. This design spreads force across the panel. It increases strength and rigidity. Panels resist bending and breaking better than traditional panels.

How do honeycomb core panels improve insulation?

The honeycomb cells trap air inside each panel. Air acts as a barrier to heat and sound. This helps keep rooms comfortable and quiet. Builders use these panels for walls and ceilings.

Are honeycomb core panels lightweight?

Yes. Honeycomb core panels weigh much less than solid panels. Aluminum honeycomb panels are up to 70 times lighter than bricks. Lightweight panels make installation faster and easier.

Can honeycomb core panels resist moisture and corrosion?

Honeycomb core panels resist moisture and corrosion. Aluminum panels stay dry in humid places. They do not rust or grow mold. This makes them durable for many environments.

Where are honeycomb core panels commonly used?

| Application Area | Example Uses |

|---|---|

| Construction | Floors, walls, ceilings |

| Air Conditioning | Ducts, cooling units |

| Transportation | Aircraft, trains, ships |

Post time: Feb-09-2026