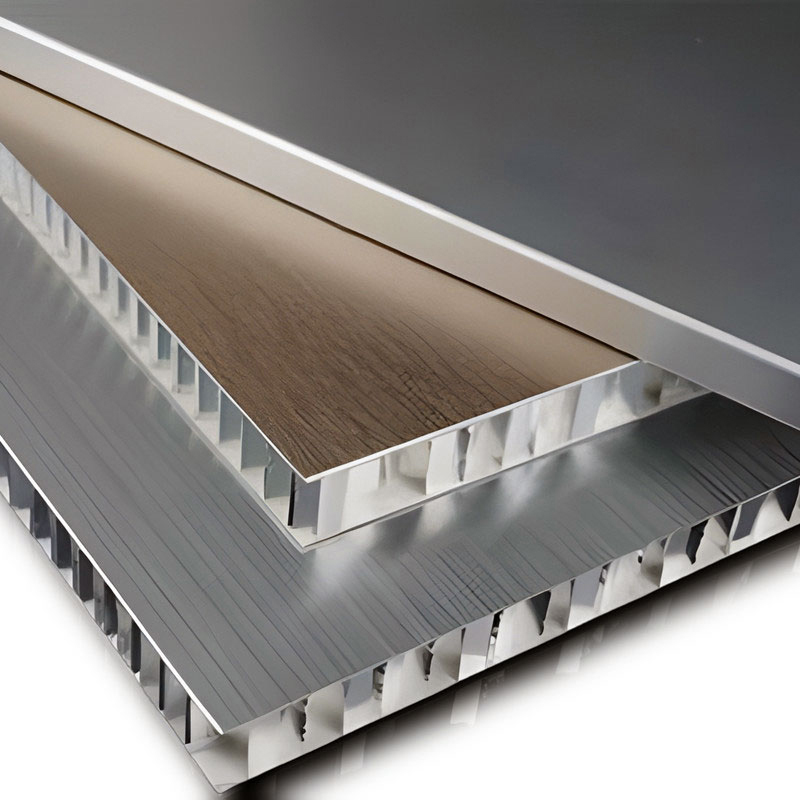

Aluminum honeycomb panels are revolutionizing architecture by offering a unique blend of strength, lightweight structure, and flexibility in design. Their core structure, made from an aluminum honeycomb sandwiched between two sheets, delivers impressive durability and flatness. These panels support innovative design possibilities and are widely used across industries.

- In construction, they appear in high-rise building facades and interior walls, providing thermal insulation and fire resistance.

- In transportation, they enhance electric vehicles, trains, buses, and even marine vessels, improving energy efficiency and passenger comfort.

Sustainability and long-term durability make these materials an essential choice for forward-thinking projects.

Aluminum Honeycomb Panels: Strength and Lightweight Advantages

High Strength-to-Weight Ratio

Honeycomb aluminum panels stand out because of their impressive strength-to-weight ratio. Engineers and architects often choose these panels for projects where both strength and lightweight profile are essential. The honeycomb core, filled with air, reduces the overall weight while maintaining high structural strength. This design allows the panels to support heavy loads without adding unnecessary weight to the building or vehicle.

The following table compares the performance of solid aluminum panels and aluminum honeycomb panels:

| Performance Index | Solid Aluminum Panel | Aluminum Honeycomb Composite Panel |

|---|---|---|

| Weight | 100% (Baseline) | 40%-60% (Honeycomb Core Filled with Air) |

| Flexural Stiffness | 100% | 80%-100% (Depending on Panel Thickness and Honeycomb Core Design) |

| Impact Resistance | Depends on Thickness | Energy Absorption via Honeycomb Core Deformation (Non-Linear Enhancement) |

| Fatigue Life | Susceptible to Failure Due to Microcracks | Honeycomb Walls Prevent Crack Propagation, Extending Life |

This table shows that honeycomb aluminum panels offer significant weight savings and maintain high strength. The honeycomb structure absorbs energy during impacts, which increases safety and durability. The panels also resist fatigue better than solid aluminum, making them ideal for long-term use in construction and transportation.

Laboratory tests confirm the load-bearing capacity of aluminum honeycomb panels. In a compression test using an Instron 5900R 4482 machine, samples with different angles of applied force reached a maximum load of 25 kN. This result demonstrates that honeycomb aluminum panels can handle demanding structural requirements.

Structural Stability and Flatness

Architects value honeycomb aluminum panels for their ability to maintain structural flatness over large spans. The sandwich construction, with two thin facing layers and a thick honeycomb core, provides excellent bending behavior and weight savings. This design ensures that the panels remain flat and stable, even when used in large-format modules.

Honeycomb aluminum panels resist warping and deformation better than many other cladding materials. Their cellular core structure minimizes dead load and supports precise alignment, which is crucial for curtain walls and facade cladding.

The following table highlights key properties of honeycomb aluminum panels:

| Property | Description |

|---|---|

| Strength | High strength suitable for demanding applications. |

| Flatness | Maintains structural flatness over large spans. |

| Lightweight | Exceptionally lightweight, enhancing ease of use in construction. |

| Durability | Offers durability while resisting corrosion. |

| Performance | Improves fire and acoustic performance, making it ideal for various applications. |

- Aluminum honeycomb core provides excellent weight savings.

- The bending behavior of these panels is advantageous for structural integrity.

- The design allows for large spans without compromising flatness.

Compared to steel honeycomb panels, aluminum honeycomb panels are lighter and offer superior corrosion resistance. These features make them suitable for a wide range of environments, from high-rise buildings to transportation vehicles.

Ease of Installation and Maintenance

Honeycomb aluminum panels simplify the installation process in construction projects. Their lightweight nature reduces the overall weight of doors, walls, and facades. This feature lessens the strain on hinges and supporting structures, making installation faster and more efficient.

The streamlined installation process saves time and labor costs, which benefits both builders and project owners.

Maintenance is also easier with honeycomb aluminum panels. The panels resist scratches and corrosion, so they require less frequent repairs. Their uniform surface makes cleaning simple, and their durability ensures long-term performance. These advantages help architects and builders deliver projects that are both cost-effective and reliable.

Modern Design and Versatility with Honeycomb Aluminum Panels

Creative Architectural Forms

Aluminum honeycomb panels support innovation in architecture. Their lightweight structure and high strength-to-weight ratio allow architects to create complex geometric shapes and elegant frameworks. Nexcomb panels, for example, are used in aviation, building, and transportation. These panels can be molded into curves, slopes, and non-linear forms. Modular honeycomb systems make installation fast and flexible, even in spaces with unique shapes.

Architects use aluminum honeycomb panels for exterior facades and ceilings in modern design projects. The panels adapt to different thicknesses and core cell sizes, giving designers more options for creative expression.

| Feature | Description |

|---|---|

| Lightweight | Suitable for innovative building materials and complex forms. |

| High strength-to-weight ratio | Essential for exterior facades and large spans. |

| Thermal efficiency | Maintains performance in diverse environments. |

| Sound insulation | Ideal for soundproofing applications across industries. |

Surface Finishes and Color Options

Aluminum honeycomb panels offer a wide range of surface finishes and color options. Manufacturers provide finishes such as mill, primer, PVDF, PE, powder coating, anodized, and tread texture. Designers can choose from metal, matt, glossy, brushed, granite, wooden, and nacreous series. Custom colors are available using RAL and Pantone codes.

- Standard colors include Timber, Stone, Metal, and Anodize series.

- Surface treatments range from embossed and mirror to high-gloss and pearl.

- Coating options like PE and PVDF enhance durability and appearance.

This versatility in finishes and colors supports innovation in modern design, allowing architects to match panels to any project style.

Applications in Interiors and Exteriors

Aluminum honeycomb panels have applications across industries. They are used for new building cladding and renovation of old structures. In homes, restaurants, hotels, and offices, these panels improve both aesthetics and functionality. Prefabricated panels make installation and maintenance easy.

- Common applications include exterior facades, curtain walls, roofs, ceilings, and interior partitions.

- Their lightweight nature enables large, seamless facades that are visually striking and structurally sound.

- Notable projects such as the Jameel Art Centre in Dubai and Nhow Rai Hotel in Amsterdam showcase the versatility of aluminum honeycomb panels in both interior decoration and facade cladding.

Aluminum honeycomb panels provide excellent thermal and sound insulation, weather resistance, and shock resistance. Their versatility makes them a preferred choice for innovative building materials in modern design.

Durability, Fire Safety, and Acoustic Performance

Long-Term Durability and Low Maintenance

Aluminum honeycomb panels offer unmatched strength and durability in modern architecture. These panels perform well in harsh environments, including the Arctic Circle, arid deserts, and humid coastlines. Their stability in extreme climates shows their long-term durability. Builders and architects choose these panels for projects that require reliable materials over many years.

- Aluminum honeycomb panels resist corrosion and maintain their appearance in challenging weather.

- They remain stable and strong in both hot and cold regions.

- Their performance does not change in humid or dry conditions.

Maintenance costs for aluminum honeycomb panels are lower than for many other cladding materials. The table below compares cleaning and repair needs:

| Aspect | Aluminum Honeycomb Panels | Other Aluminum Cladding | Other Cladding Materials |

|---|---|---|---|

| Cleaning | Low maintenance, regular cleaning needed | Low maintenance, regular cleaning needed | Varies, often requires more upkeep |

| Repairs | Touch-ups or panel replacements needed | Minimal repairs needed | Often requires more extensive repairs |

This low-maintenance feature adds to the overall durability of the panels.

Fire Resistance and Safety Features

Safety is a top priority in building design. Aluminum honeycomb panels meet strict fire safety standards, making them suitable for commercial construction. The panels have earned certifications such as EN 13501-1 with a fire resistance level of FR A1. This means they do not contribute to fire, smoke, or toxic emissions.

| Certification Standard | Fire Resistance Level | Key Features |

|---|---|---|

| EN 13501-1 | FR A1 | Non-combustibility, zero contribution to fire, smoke, or toxic emissions |

These safety features help protect people and property in case of fire.

Sound and Thermal Insulation

Aluminum honeycomb panels also improve acoustic and thermal comfort. Laboratory tests show that these panels provide effective sound insulation across a wide range of frequencies. The honeycomb core reduces noise, making buildings quieter and more comfortable.

| Measurement Aspect | Details |

|---|---|

| Measurement Standards | ISO 10140:2010, ASTM E 90:2004 |

| TL Similarity Range | Honeycomb and honeycomb perforated panels similar at 352 Hz–512 Hz |

| TL Difference in Specific Ranges | Honeycomb perforated panel: ~3 dB higher than honeycomb panel at 690 Hz–1040 Hz and 1160 Hz–1600 Hz |

Thermal insulation is another benefit. The closed cells in the honeycomb core trap air, which helps reduce indoor heat loss in winter and blocks outdoor heat in summer. This natural barrier lowers energy use for heating and cooling. The honeycomb structure keeps indoor temperatures comfortable all year.

Aluminum honeycomb panels combine durability, fire safety, and insulation to create safer and more efficient buildings.

Sustainability and Environmental Impact

Energy Efficiency and Eco-Friendly Materials

Aluminum honeycomb panels play a key role in helping projects achieve sustainable building goals. These panels are often made from recycled aluminum. This process saves up to 95% of the energy needed to produce new aluminum. Using recycled materials reduces the demand for raw resources and supports eco-friendliness in construction. The lightweight design of these panels also lowers transportation costs and emissions. Fewer trucks are needed to deliver materials to commercial construction sites, which means less fuel is used.

The excellent thermal insulation of aluminum honeycomb panels helps buildings use less energy for heating and cooling. This feature supports energy efficiency credits in green building standards like LEED and BREEAM. Builders can install these panels quickly and with little waste because of their modular design. This approach fits well with the growing focus on sustainability and eco-friendliness in modern architecture.

Note: Choosing aluminum honeycomb panels can help architects and builders meet strict environmental requirements while creating comfortable and efficient spaces.

Recyclability and Reduced Environmental Footprint

Aluminum honeycomb panels help reduce the overall environmental footprint of construction projects in several ways:

- Use fewer resources during transport and installation

- Improve thermal behavior, which lowers energy use

- Are fully recyclable at the end of their life cycle

- Are lighter and faster to install compared to stone, ceramic, or concrete

- Create far less wastage on site

The table below shows how these panels compare to traditional materials:

| Feature | Aluminum Honeycomb Panel | Stone/Ceramic/Concrete |

|---|---|---|

| Weight | Very light | Heavy |

| Installation Speed | Fast | Slow |

| Recyclability | High | Low |

| Waste Generation | Minimal | Significant |

By choosing aluminum honeycomb panels, builders support sustainability in construction and help protect the environment for future generations.

Real-World Applications and Selection Guide

Iconic Projects and Case Studies

Aluminum honeycomb panels have shaped many landmark buildings around the world. Their performance and design flexibility make them a top choice for architects who are pioneering the future of construction. The following table highlights several iconic projects that showcase the use of high-performing materials:

| Project Name | Location | Description |

|---|---|---|

| Nhow Rai Hotel | Amsterdam, The Netherlands | Iconic hotel featuring aluminum honeycomb panels, designed by OMA, achieving aesthetic and wind load requirements. |

| MIT Kendall Station | Cambridge, USA | Features highly reflective anodized honeycomb panels on the ceiling of an inverted boat structure. |

| Hayy Jameel Art Centre | Jeddah, KSA | New art center utilizing aluminum honeycomb panels in its architectural design. |

These projects demonstrate how aluminum honeycomb panels deliver outstanding performance in both appearance and durability. Their use in major buildings signals the future of construction.

Choosing the Right Panel for Your Project

Selecting the best aluminum honeycomb panel depends on several important criteria. Architects and builders should consider both performance and design needs. The table below outlines key factors:

| Criteria | Description |

|---|---|

| Fire Rating | Essential for safety, with many panels achieving high ratings like A2 under EN 13501-1. Specialized fireproof panels are available. |

| Sound and Heat Insulation | The honeycomb structure provides natural insulation, improving energy efficiency and comfort. Thicker panels enhance sound insulation. |

| Impact Resistance | The structure absorbs impact forces, making the panels durable against external damage. |

| Corrosion Resistance | Aluminum’s inherent properties and surface treatments make it suitable for various environments. |

| Environmental Impact | Aluminum is recyclable, contributing to sustainability and potential green building certifications. |

| Supplier Reputation | Important to evaluate suppliers’ expertise and relevant certifications for quality assurance. |

Careful selection ensures the panels meet the performance requirements of each project and support the future of construction.

Installation and Maintenance Tips

Proper installation and maintenance help maximize the performance of aluminum honeycomb panels. Builders should follow these best practices:

- Surface and material preparation: Inspect panels for defects and clean surfaces before installation.

- Precision in measurements: Verify panel dimensions and maintain consistent spacing.

- Environmental factors: Install in suitable temperatures and account for thermal expansion.

- Structural stability: Confirm the load-bearing capacity of the frame and use secure fasteners.

- Waterproofing and sealing: Treat joints with weather-resistant sealants and add drainage systems.

- Safety considerations: Use safety equipment for high-rise installations and ensure electrical systems are insulated.

Tip: Regular inspections and cleaning help maintain the panels’ performance and design quality over time.

Aluminum honeycomb panels continue to lead the way as high-performing materials, supporting the future of construction in both commercial and residential projects.

Aluminum honeycomb panels are changing the way architects design buildings. These panels offer strength, light weight, and flexible design options. Builders choose them for their durability and eco-friendly qualities. The future looks bright for this material.

- Demand for lightweight composites is rising each year.

- Greener building practices and energy-saving designs drive growth.

- New manufacturing methods improve reliability and versatility.

Aluminum honeycomb panels help create safer, quieter, and more comfortable spaces. Architects and builders can expect even more innovation ahead.

FAQ

What are aluminum honeycomb panels made of?

Aluminum honeycomb panels use two thin aluminum sheets and a honeycomb-shaped aluminum core. This design gives the panels strength and keeps them lightweight. The honeycomb core also helps with insulation and durability.

Where can aluminum honeycomb panels be used?

You can use these panels in building facades, ceilings, walls, and floors. They also work well in transportation, such as trains, ships, and airplanes. Many architects use them for both interior and exterior decoration.

How do aluminum honeycomb panels improve energy efficiency?

The honeycomb core traps air inside the panel. This helps reduce heat loss in winter and keeps buildings cooler in summer. Buildings use less energy for heating and cooling when they use these panels.

Are aluminum honeycomb panels easy to install?

Yes. The panels are lightweight and easy to handle. Builders can cut and fit them quickly. The smooth surface makes cleaning simple, and the panels need little maintenance.

Can aluminum honeycomb panels be recycled?

Absolutely! Aluminum honeycomb panels are fully recyclable. Recycling aluminum saves energy and reduces waste. Many green building projects choose these panels for their eco-friendly benefits.

Post time: Jan-26-2026