Product Description

1. Cost Reduction in Manufacturing

One of the primary advantages of using compressed aluminum honeycomb cores in large-scale production is the substantial reduction in manufacturing costs. The efficient production process of honeycomb cores allows for bulk manufacturing, which typically results in economies of scale. As the volume of production increases, the cost per unit decreases, enabling businesses to produce more while spending less. This cost-effectiveness directly translates into higher profit margins for customers.

2. Lower Transportation Costs

When aluminum honeycomb cores are delivered in a compressed format, the shipping costs are substantially lowered. Transporting lightweight and compact products enables distributors and manufacturers to maximize the load capacity of shipping vehicles, reducing the overall freight expenses. This efficiency in logistics means that businesses can allocate their resources more effectively, ultimately enhancing their profitability.

3. Customization for Market Needs

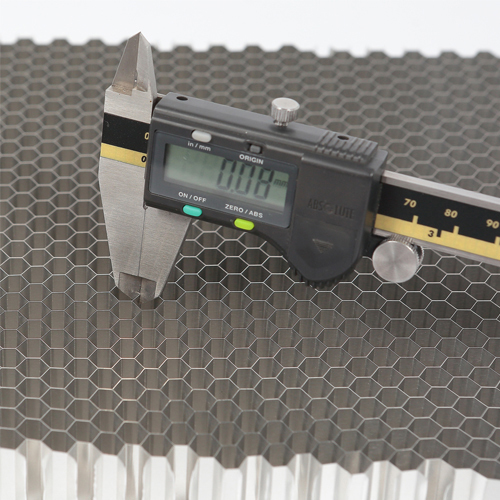

The ability to customize aluminum honeycomb cores according to specific requirements makes them a favored choice among manufacturers. Customers can specify dimensions, cell sizes, and other characteristics tailored to their unique applications. This flexibility allows businesses to meet the evolving demands of the market swiftly and efficiently, ensuring they remain competitive and relevant. Customization not only aids in product differentiation but also helps businesses better satisfy customer needs, leading to increased sales.

4. Enhanced Product Performance

Due to their lightweight yet sturdy structure, compressed aluminum honeycomb cores contribute to improved product performance. By incorporating these cores, customers can produce lighter products without sacrificing durability and strength. This advantage is particularly vital in industries such as aerospace and automotive, where reducing weight can lead to enhanced fuel efficiency and performance. Products that perform better tend to attract more customers and can command higher market prices.

5. Increased Profit Margins

With lower production and transport costs combined with custom options and superior product performance, businesses can enjoy significant increases in their profit margins. Compressed aluminum honeycomb cores allow for a strategic pricing model that not only covers costs but also adds a healthy margin. Companies can reinvest these profits into research and development, marketing, or expanding their product lines, fueling growth and innovation.

6. Sustainability Benefits

In today’s market, sustainability is increasingly important to consumers and businesses alike. Aluminum is a highly recyclable material. By opting for aluminum honeycomb cores, companies can highlight their commitment to sustainability, attracting eco-conscious customers and potentially increasing their market share.

In summary, purchasing compressed aluminum honeycomb core products for large-scale production presents numerous advantages that significantly enhance a customer’s procurement strategy. From lowering manufacturing and transportation costs to offering customization and improving product performance, these features create a robust framework for increased profitability. As businesses continue to seek ways to optimize their operations and elevate their market position, investing in aluminum honeycomb cores represents a strategic decision that pays dividends in efficiency and profitability.

Honeycomb core of Density and Falt compressive strength.

|

Honeycomb Core Foil Thickness/Length(mm) |

Density Kg/ m² |

Compressive Strength 6Mpa |

Remarks |

|

0.05/3 |

68 |

1.6 |

3003H19 15mm |

|

0.05/4 |

52 |

1.2 |

|

|

0.05/5 |

41 |

0.8 |

|

|

0.05/6 |

35 |

0.7 |

|

|

0.05/8 |

26 |

0.4 |

|

|

0.05/10 |

20 |

0.3 |

|

|

0.06/3 |

83 |

2.4 |

|

|

0.06/4 |

62 |

1.5 |

|

|

0.06/5 |

50 |

1.2 |

|

|

0.06/6 |

41 |

0.9 |

|

|

0.06/8 |

31 |

0.6 |

|

|

0.06/10 |

25 |

0.4 |

|

|

0.07/3 |

97 |

3.0 |

|

|

0.07/4 |

73 |

2.3 |

|

|

0.07/5 |

58 |

1.5 |

|

|

0.07/6 |

49 |

1.2 |

|

|

0.07/8 |

36 |

0.8 |

|

|

0.07/10 |

29 |

0.5 |

|

|

0.08/3 |

111 |

3.5 |

|

|

0.08/4 |

83 |

3.0 |

|

|

0.08/5 |

66 |

2.0 |

|

|

0.08/6 |

55 |

1.0 |

|

|

0.08/8 |

41 |

0.9 |

|

|

0.08/10 |

33 |

0.6 |

|

Item |

Units |

Specification |

||||||||

|

Cell |

Inch |

|

1/8" |

|

|

3/16" |

|

1/4" |

|

|

|

mm |

2.6 |

3.18 |

3.46 |

4.33 |

4.76 |

5.2 |

6.35 |

6.9 |

8.66 |

|

|

Side |

mm |

1.5 |

1.83 |

2 |

2.5 |

2.75 |

3 |

3.7 |

4 |

5 |

|

Fiol thickness |

mm |

0.03~0.05 |

0.03~0.05 |

0.03~0.05 |

0.03~0.06 |

0.03~0.06 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

|

Width |

mm |

440 |

440 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

|

Length |

mm |

1500 |

2000 |

3000 |

3000 |

3000 |

4000 |

4000 |

4000 |

5500 |

|

High |

mm |

1.7-150 |

1.7-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

|

|

||||||||||

|

Item |

Units |

Specification |

||||||||

|

Cell |

Inch |

3/8" |

|

1/2" |

|

|

3/4" |

|

1" |

|

|

mm |

9.53 |

10.39 |

12.7 |

13.86 |

17.32 |

19.05 |

20.78 |

25.4 |

||

|

Side |

mm |

5.5 |

6 |

|

8 |

10 |

11 |

12 |

15 |

|

|

Fiol thickness |

mm |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

|

|

Width |

mm |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

|

|

Length |

mm |

5700 |

6000 |

7500 |

8000 |

10000 |

11000 |

12000 |

15000 |

|

|

High |

mm |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

|

|

|

||||||||||

|

1.Also we can customize according to the demand of clients |

||||||||||