Customization and Versatility in Application

One of the primary benefits of aluminum honeycomb core blocks is their capacity for customization according to specific market demands. By delivering the product in its full block form, manufacturers allow customers to tailor the dimensions and shapes to suit a wide range of applications. This adaptability is particularly valuable in sectors such as aerospace, automotive, construction, and furniture design, where the need for specialized shapes and sizes can vary dramatically depending on project requirements.

Customers are granted the freedom to execute cutting based on their unique specifications, which means they can optimize the material for their particular use cases. For example, in industries where lightweight materials are essential for efficiency and performance, companies can precisely cut the core blocks to create parts that fit perfectly into their designs, ultimately enhancing product functionality.

Increased Efficiency and Reduced Waste

The ability to cut aluminum honeycomb blocks as needed not only increases the efficiency of material use but also minimizes waste. Customers can make adjustments to the cutting process according to real-time requirements, which helps them optimize their manufacturing workflows. This flexibility allows for just-in-time production, reducing excess inventory and aligning production schedules more closely with market demand.

Investment in Specialized Cutting Equipment

While the utilization of aluminum honeycomb core blocks offers numerous advantages, it is essential to acknowledge the need for specialized cutting equipment. Investing in professional cutting machinery is a crucial step for businesses looking to leverage these core blocks effectively. Such equipment ensures precise cuts, maintaining the integrity of the honeycomb structure and preserving the benefits of lightweight and strength.

By having the right tools, manufacturers can enhance their capability to respond quickly to customer orders, adjust designs, and produce high-quality components that meet stringent industry standards. This investment not only enhances operational efficiency but also boosts overall productivity, allowing businesses to scale their operations without compromising quality.

Commercial Value and Competitive Advantage

From a commercial perspective, the use of aluminum honeycomb core blocks presents substantial potential for businesses looking to differentiate themselves in competitive markets. The flexibility to produce custom solutions quickly can set a company apart from competitors who may struggle with more rigid manufacturing processes. Businesses that can respond faster to changing customer demands are better positioned to capture new contracts and foster long-term relationships with clients.

Moreover, by promoting the sustainability of aluminum—an infinitely recyclable material—companies can market their products as environmentally friendly, which is increasingly important to consumers. This alignment with sustainability initiatives can further enhance a company’s brand value, attracting a broader customer base.

In conclusion, aluminum honeycomb core blocks offer a compelling solution for businesses seeking to enhance their manufacturing processes and meet diverse market demands. With their customizable nature and reduced waste potential, these blocks not only enhance operational efficiency but also unlock significant commercial value. As companies invest in specialized cutting equipment and embrace the flexibility of these products, they position themselves for success in an ever-evolving marketplace. The strategic use of aluminum honeycomb core blocks can serve as a catalyst for growth, innovation, and competitive advantage across various industries.

Honeycomb core of Density and Falt compressive strength.

|

Honeycomb Core Foil Thickness/Length(mm) |

Density Kg/ m² |

Compressive Strength 6Mpa |

Remarks |

|

0.05/3 |

68 |

1.6 |

3003H19 15mm |

|

0.05/4 |

52 |

1.2 |

|

|

0.05/5 |

41 |

0.8 |

|

|

0.05/6 |

35 |

0.7 |

|

|

0.05/8 |

26 |

0.4 |

|

|

0.05/10 |

20 |

0.3 |

|

|

0.06/3 |

83 |

2.4 |

|

|

0.06/4 |

62 |

1.5 |

|

|

0.06/5 |

50 |

1.2 |

|

|

0.06/6 |

41 |

0.9 |

|

|

0.06/8 |

31 |

0.6 |

|

|

0.06/10 |

25 |

0.4 |

|

|

0.07/3 |

97 |

3.0 |

|

|

0.07/4 |

73 |

2.3 |

|

|

0.07/5 |

58 |

1.5 |

|

|

0.07/6 |

49 |

1.2 |

|

|

0.07/8 |

36 |

0.8 |

|

|

0.07/10 |

29 |

0.5 |

|

|

0.08/3 |

111 |

3.5 |

|

|

0.08/4 |

83 |

3.0 |

|

|

0.08/5 |

66 |

2.0 |

|

|

0.08/6 |

55 |

1.0 |

|

|

0.08/8 |

41 |

0.9 |

|

|

0.08/10 |

33 |

0.6 |

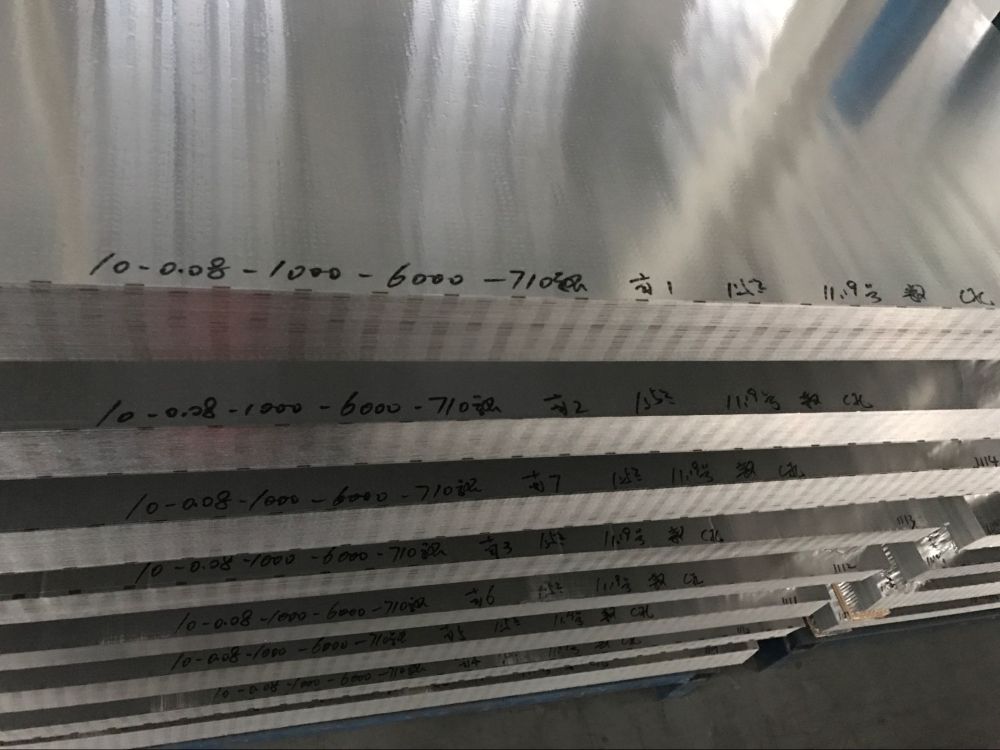

Conventional size specifications

|

Item |

Units |

Specification |

||||||||

|

Cell |

Inch |

|

1/8" |

|

|

3/16" |

|

1/4" |

|

|

|

mm |

2.6 |

3.18 |

3.46 |

4.33 |

4.76 |

5.2 |

6.35 |

6.9 |

8.66 |

|

|

Side |

mm |

1.5 |

1.83 |

2 |

2.5 |

2.75 |

3 |

3.7 |

4 |

5 |

|

Fiol thickness |

mm |

0.03~0.05 |

0.03~0.05 |

0.03~0.05 |

0.03~0.06 |

0.03~0.06 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

|

Width |

mm |

440 |

440 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

|

Length |

mm |

1500 |

2000 |

3000 |

3000 |

3000 |

4000 |

4000 |

4000 |

5500 |

|

High |

mm |

1.7-150 |

1.7-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

|

|

||||||||||

|

Item |

Units |

Specification |

||||||||

|

Cell |

Inch |

3/8" |

|

1/2" |

|

|

3/4" |

|

1" |

|

|

mm |

9.53 |

10.39 |

12.7 |

13.86 |

17.32 |

19.05 |

20.78 |

25.4 |

||

|

Side |

mm |

5.5 |

6 |

|

8 |

10 |

11 |

12 |

15 |

|

|

Fiol thickness |

mm |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

|

|

Width |

mm |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

|

|

Length |

mm |

5700 |

6000 |

7500 |

8000 |

10000 |

11000 |

12000 |

15000 |

|

|

High |

mm |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

|

|

|

||||||||||

|

1.Also we can customize according to the demand of clients |

||||||||||