-

Aluminum honeycomb core expanded application to Air condition

The unique features of our aluminum honeycomb core extensions make them ideal for a variety of applications. The hexagonal cell structure provides excellent strength and rigidity, resulting in enhanced load-bearing capacity. Its lightweight nature makes it easy to handle and install, reducing labor costs and time. In addition, our core materials have excellent thermal and acoustic insulation properties, making them ideal for air conditioning system applications.

The use of our aluminum honeycomb cores in air conditioners has revolutionized the industry, taking the efficiency and performance of these systems to new heights. The honeycomb structure allows for optimal air distribution, ensuring equal cooling and ventilation in every corner of the space. Not only does this improve comfort, it also helps save energy, making it an environmentally friendly choice.

-

Aluminum Honeycomb Core With Composite of Variety Plates

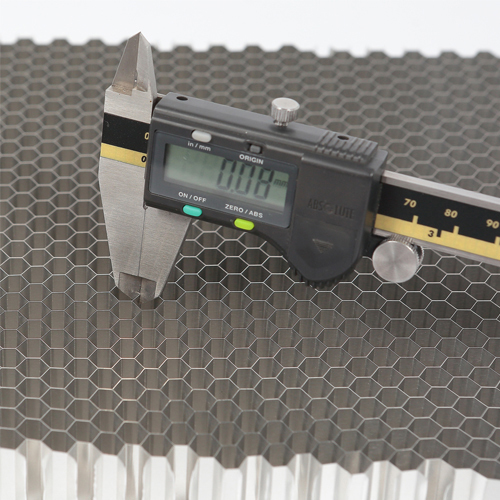

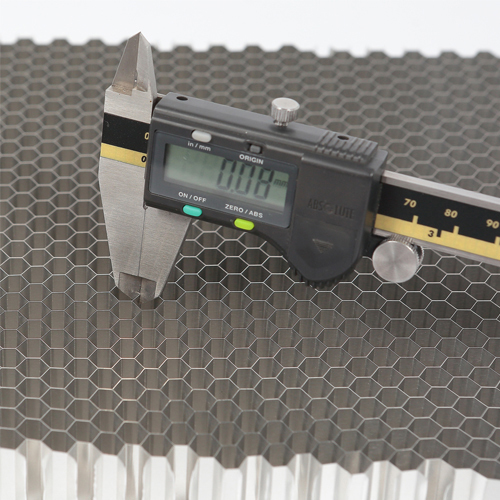

Aluminum honeycomb core is made up of layers and aluminum foil adhesive, overlying, and then stretched into a regular hexagonal honeycomb core. Aluminum honeycomb core hole wall with sharp, clear, without burrs, suitable for high quality across the core material of adhesive and other purpose. Honeycomb board core layer is hexagonal aluminum honeycomb structure, containment of dense honeycomb like many wall beams, can bear the pressure from the other side of the panel, the plate force uniform, ensure the panel in a large area can still keep high flatness. In addition, the hollow honeycomb can also greatly abate the plate body thermal expansion. In the form of the supply full blocks of honeycomb. Cut slices of honeycomb, expanded honeycomb, perforated honeycomb, corrosion treated honeycomb.

-

Advantages of Purchasing Compressed Aluminum Honeycomb Core Products for Scaled Production

Compressed aluminum honeycomb core products are increasingly recognized for their significant advantages in large-scale production and customized applications. By leveraging these benefits, customers can greatly enhance their economic efficiency and product profitability. Here are several key advantages that make these products particularly appealing for bulk purchasing.

-

Compressed Aluminum Honeycomb Core Products: A Comprehensive Overview Introduction

Aluminum honeycomb core products have gained significant traction in various industries, particularly in aerospace, automotive, and construction sectors. These products offer an exceptional strength-to-weight ratio, making them ideal for applications where lightweight materials are essential without compromising structural integrity. One popular delivery form of these products is the compressed aluminum honeycomb core, commonly referred to as “compressed form.”,“Unexpanded form”. This article will explore the characteristics, advantages, and disadvantages of compressed aluminum honeycomb cores in detail.

-

Aluminum Honeycomb Core Blocks: Meeting Demand and Unlocking Commercial Value

Aluminum honeycomb core blocks are an innovative solution designed to streamline the production and customization processes in various industries. These blocks, delivered as complete entities and retaining the final cutting stage, provide significant advantages in terms of flexibility, usability, and commercial application. Here’s an in-depth look at the demand for honeycomb core blocks and their potential commercial value.