Product Description

What is Compressed Aluminum Honeycomb Core?

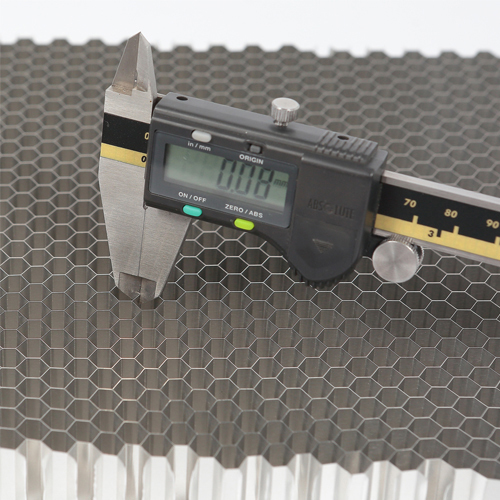

Compressed aluminum honeycomb core products consist of hexagonal aluminum cells that are bonded together to form a lightweight, stable structure. The honeycomb core is manufactured using aluminum foil, which is then expanded to create the characteristic honeycomb structure. In the compressed form, these products are packaged and delivered in a compact state to minimize transportation costs and save space.

Compressed aluminum honeycomb core products present a unique solution in various industries, offering significant advantages in transportation efficiency, cost savings, and versatility. However, challenges in handling, installation, and quality control must be acknowledged to ensure successful application. By understanding both the benefits and limitations of these products, manufacturers and consumers can make informed decisions that best suit their needs. As technology advances, innovations in materials and handling processes may further enhance the usability of compressed aluminum honeycomb cores, paving the way for even broader applications in the future.

|

Honeycomb Core Foil Thickness/Length(mm) |

Density Kg/ m² |

Compressive Strength 6Mpa |

Remarks |

|

0.05/3 |

68 |

1.6 |

3003H19 15mm |

|

0.05/4 |

52 |

1.2 |

|

|

0.05/5 |

41 |

0.8 |

|

|

0.05/6 |

35 |

0.7 |

|

|

0.05/8 |

26 |

0.4 |

|

|

0.05/10 |

20 |

0.3 |

|

|

0.06/3 |

83 |

2.4 |

|

|

0.06/4 |

62 |

1.5 |

|

|

0.06/5 |

50 |

1.2 |

|

|

0.06/6 |

41 |

0.9 |

|

|

0.06/8 |

31 |

0.6 |

|

|

0.06/10 |

25 |

0.4 |

|

|

0.07/3 |

97 |

3.0 |

|

|

0.07/4 |

73 |

2.3 |

|

|

0.07/5 |

58 |

1.5 |

|

|

0.07/6 |

49 |

1.2 |

|

|

0.07/8 |

36 |

0.8 |

|

|

0.07/10 |

29 |

0.5 |

|

|

0.08/3 |

111 |

3.5 |

|

|

0.08/4 |

83 |

3.0 |

|

|

0.08/5 |

66 |

2.0 |

|

|

0.08/6 |

55 |

1.0 |

|

|

0.08/8 |

41 |

0.9 |

|

|

0.08/10 |

33 |

0.6 |

|

Item |

Units |

Specification |

||||||||

|

Cell |

Inch |

|

1/8" |

|

|

3/16" |

|

1/4" |

|

|

|

mm |

2.6 |

3.18 |

3.46 |

4.33 |

4.76 |

5.2 |

6.35 |

6.9 |

8.66 |

|

|

Side |

mm |

1.5 |

1.83 |

2 |

2.5 |

2.75 |

3 |

3.7 |

4 |

5 |

|

Fiol thickness |

mm |

0.03~0.05 |

0.03~0.05 |

0.03~0.05 |

0.03~0.06 |

0.03~0.06 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

|

Width |

mm |

440 |

440 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

|

Length |

mm |

1500 |

2000 |

3000 |

3000 |

3000 |

4000 |

4000 |

4000 |

5500 |

|

High |

mm |

1.7-150 |

1.7-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

|

|

||||||||||

|

Item |

Units |

Specification |

||||||||

|

Cell |

Inch |

3/8" |

|

1/2" |

|

|

3/4" |

|

1" |

|

|

mm |

9.53 |

10.39 |

12.7 |

13.86 |

17.32 |

19.05 |

20.78 |

25.4 |

||

|

Side |

mm |

5.5 |

6 |

|

8 |

10 |

11 |

12 |

15 |

|

|

Fiol thickness |

mm |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

0.03~0.08 |

|

|

Width |

mm |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

1800 |

|

|

Length |

mm |

5700 |

6000 |

7500 |

8000 |

10000 |

11000 |

12000 |

15000 |

|

|

High |

mm |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

3-150 |

|

|

|

||||||||||

|

1.Also we can customize according to the demand of clients |

||||||||||