Product Description

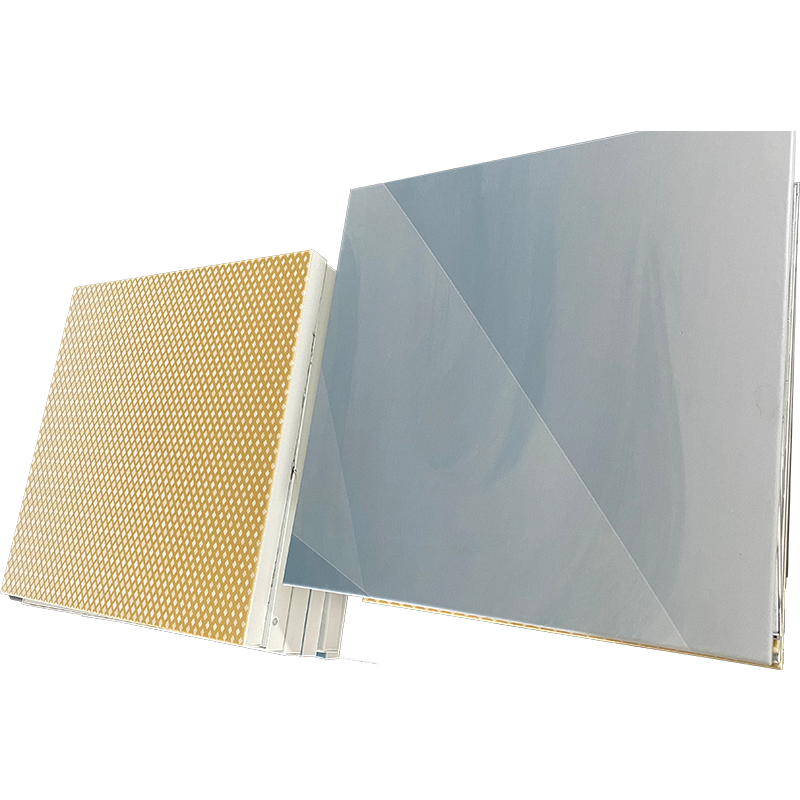

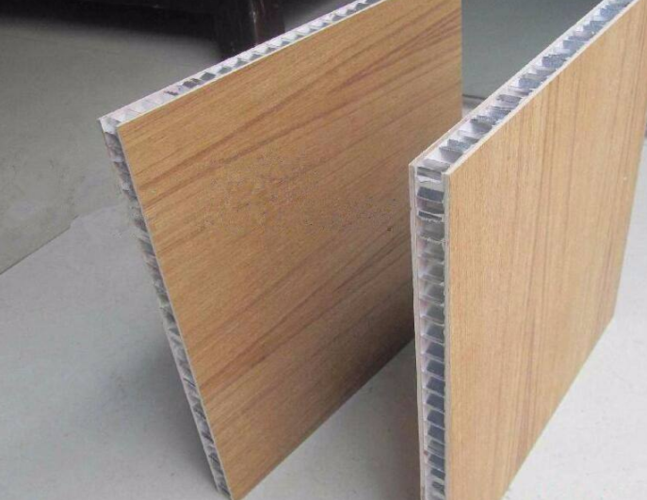

This unique combination results in a product that is fire, water, weatherproof and durable. PVC film can be embossed with various patterns such as wood grain, stone grain, brick grain, fabric, leather, camouflage, frost, sheepskin, orange peel, refrigerator pattern, etc., combining beauty and corrosion resistance.

Following are the main features of our PVC laminated honeycomb panels:

Versatility: With a variety of print patterns available, including hundreds of woodgrain options and contemporary designs, this panel can be customized for different settings and uses. Excellent processing performance: metal sheets and PVC films have good elongation, and can be easily cut, bent, roll-formed, punched, etc.

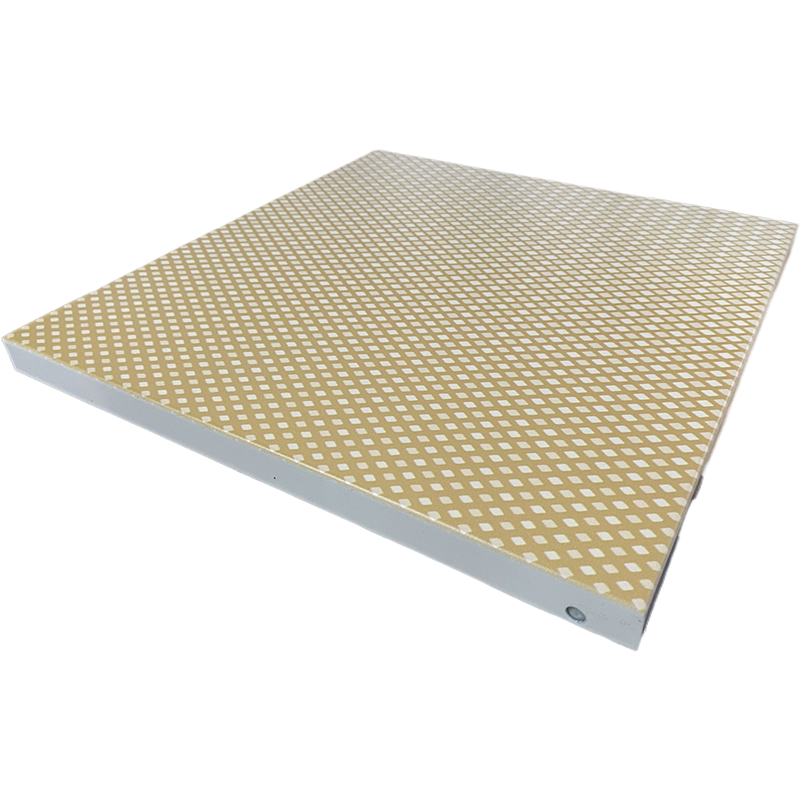

Dust Resistant, Bacteria Balance: The PVC film effectively isolates air and moisture from the metal sheet, making it dust and mildew resistant, ideal for modern interiors.

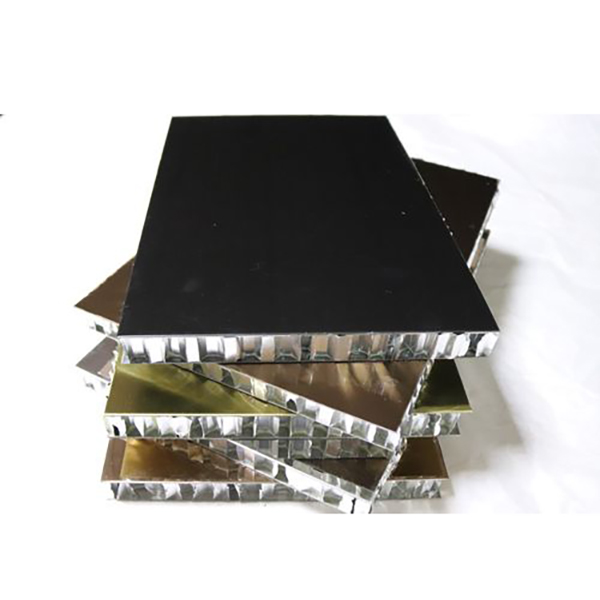

Acid and alkali resistance: The base metal has excellent anti-corrosion and acid and alkali resistance, providing excellent chemical resistance.

Fire resistance: Our PVC laminate is made of a unique fire-resistant PVC film material, which is a flame-retardant material and reaches the B1 fire rating.

Durability: The PVC film is tightly bonded to the metal plate to ensure long-lasting durability. The surface is easy to maintain and offers an economical solution.

Weather resistance: PVC film can be added with anti-ultraviolet additives, which can prevent fading during long-term outdoor use.

Environmental protection: The surface of the product made of PVC laminate is easy to clean and scratch-resistant, reducing maintenance costs and labor costs. It complies with environmental and user-friendly product standards.

Application

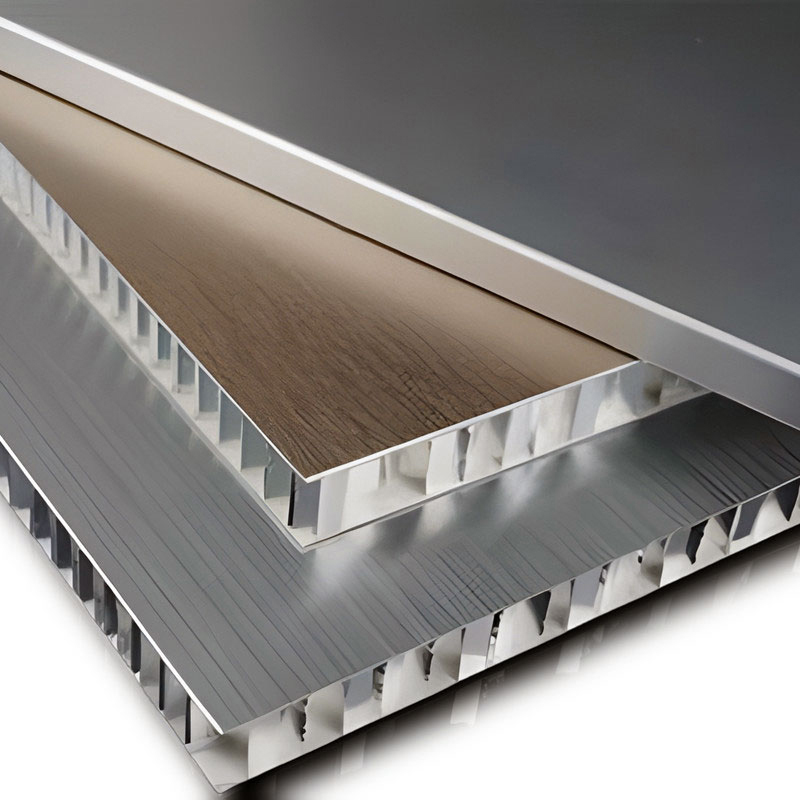

Doors: Suitable for a variety of door types, including steel and wood doors, security doors, fire doors, rolling doors, garage doors, door and window frames, etc.

Electrical appliances: very suitable for refrigerators, freezers, washing machines, air conditioners, fans, lighting fixtures, solar water heaters, electric water heaters and other applications.

Transportation: It can be used for ship carriages and interior panels, automobile interior panels, train partitions, interior panels, etc.

Furniture: Great for wardrobes, dining tables, chairs, coffee tables, lockers, filing cabinets, bookshelves, office cabinets and more.

Construction: suitable for interior and exterior walls, roofs, partitions, ceilings, door heads, factory wall panels, kiosks, garages, ventilation ducts, etc.

Office: It can be used for elevator interior decoration, copier cabinets, vending machines, computer casings, switch cabinets, instrument cabinets, tool cabinets, etc.

Experience a seamless blend of beauty and durability with our PVC laminated honeycomb panels. Enhance your space with our innovative solutions.